Metal Surface Treatment Processes

How can steel be protected against the erosion of wind and rain? How can aluminum parts exhibit a vibrant, colorful finish? And how can engine components withstand severe friction? The answer to all these questions lies inmetal surface treatment processes. Like an “invisible armor” for metals, these processes not only significantly enhance corrosion resistance, wear resistance, and aesthetics, but also impart special functional properties. This article will take you on an in-depth exploration of several core metal surface treatment techniques, explaining how they enhance the performance and value of metal products from the inside out.

Surface treatment processes refer to the technical methods that use modern physics, chemistry, metallurgy, and heat treatment to modify the condition and properties of a part’s surface, optimizing its combination with the core material to achieve the desired performance requirements.

Functions of surface treatment: Surface treatment enhances key properties such as corrosion resistance, wear resistance, and fatigue strength, while also improving aesthetics, friction coefficient, electrical conductivity or insulation, weldability, and surface roughness. In addition, it can relieve residual stresses in metal components, ensuring dimensional stability.

Surface treatment processes can be broadly divided into four categories: surface modification techniques, surface alloying techniques, surface conversion coating techniques, and surface coating techniques.

Surface modification techniques refer to surface treatment processes that alter the morphology, phase composition, microstructure, defect state, or stress state of a material’s surface through physical, chemical, or other methods to achieve the desired performance, while keeping the material’s chemical composition unchanged. Typical processes includesurface quenching, laser surface hardening, shot peening, rolling, drawing, and polishing.

Surface alloying techniques refer to surface treatment processes in which additional materials are introduced into the substrate by physical methods to form an alloyed layer, thereby achieving the desired performance. Examples include carburizing and nitriding.

Surface conversion coating techniques refer to surface treatment processes in which added materials chemically react with the substrate to form a conversion coating, thereby achieving the desired performance. Examples include blackening, phosphating, and anodizing.

Surface coating techniques refer to surface treatment processes in which additional materials are applied onto the substrate by physical or chemical methods to form a plated or coated layer, thereby achieving the desired performance, without the substrate participating in the formation of the coating. Examples include thermal spraying, vacuum deposition, electroplating, and vapor deposition (Physical Vapor Deposition, PVD / Chemical Vapor Deposition, CVD).

How to choose the appropriate surface treatment for metal components? This depends on three key factors:material type, working environment, and performance requirements. Below, we provide a detailed guide to recommended surface treatment processes for several commonly used metal materials.

Carbon steel (S45C, SS400): These materials have relatively low hardness and are prone to oxidation and corrosion. Therefore, they are commonly treated with galvanizing, chrome plating, nitriding, phosphating, blackening, or sandblasting.

The figure shows a component made of SS400that has undergone white zinc plating. This treatment not only provides corrosion protectionbut also gives the part a clean and modern aesthetic.

The figure shows a component made of S45C with a surface treated by nitriding followed by sandblasting. The nitriding process imparts the surface with high hardness, excellent wear resistance, enhanced fatigue strength, and good corrosion resistance. Sandblasting after nitriding cleans the surface and provides a matte finish.

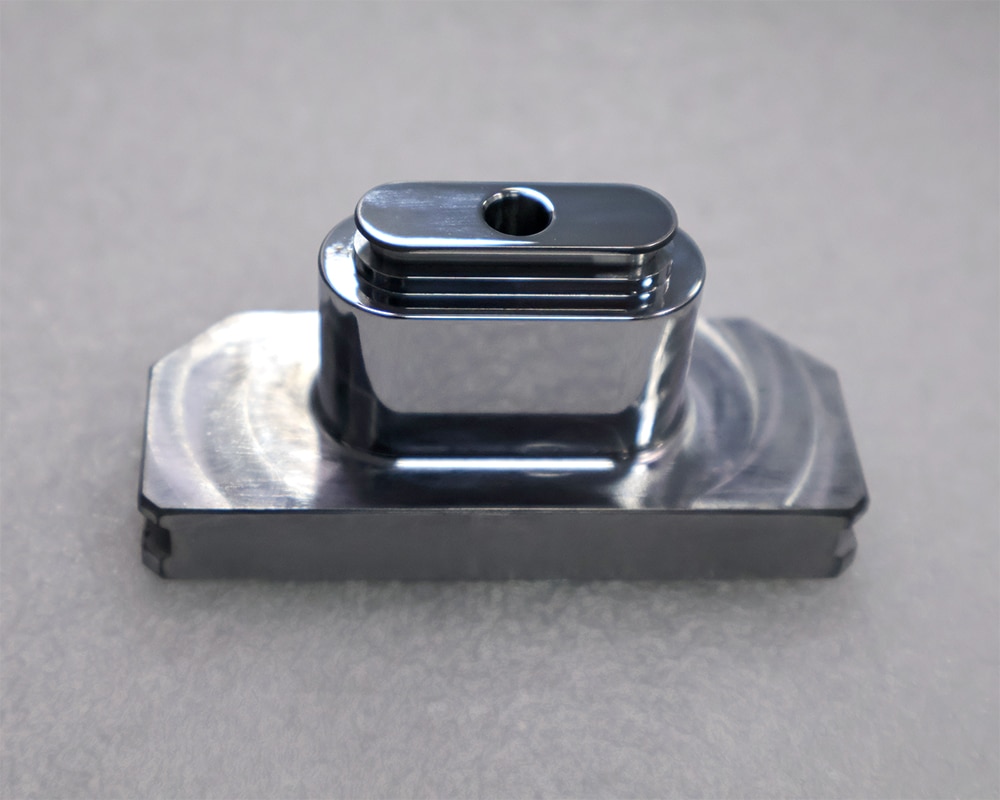

The figure shows a component made of S45C with a surface chrome-plated. Chrome plating not only enhances the hardness and wear resistance of the metal part but also gives it an excellent metallic finish and aesthetic appeal.

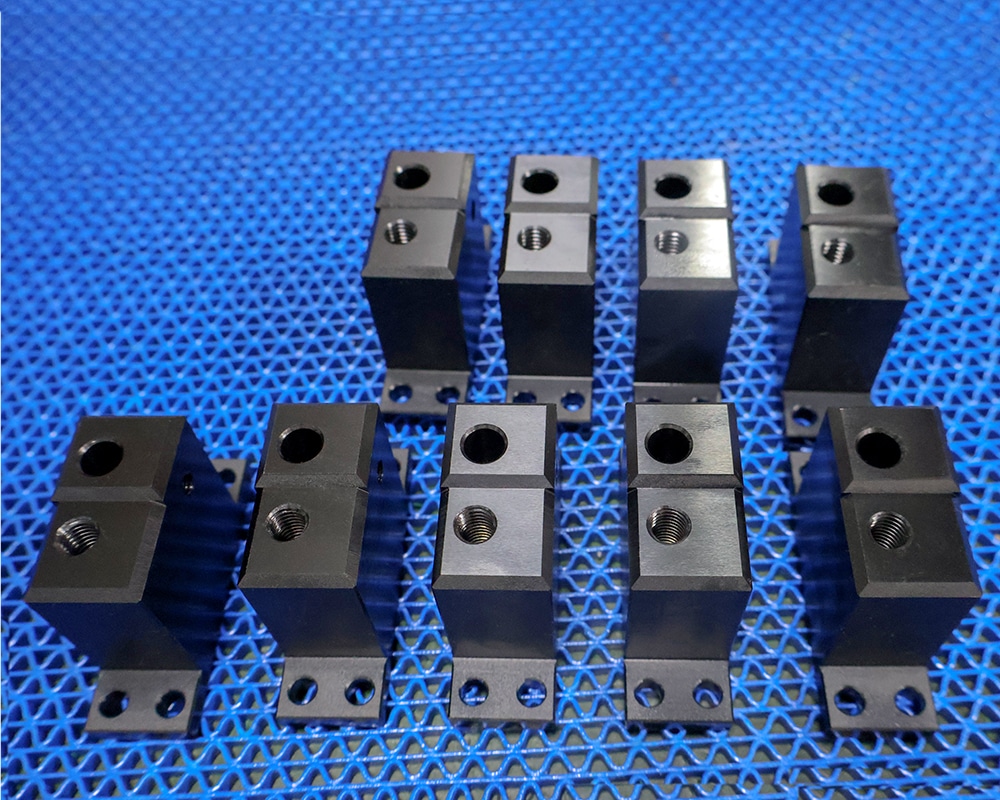

This process involves heating steel parts in air–steam or chemical solutions to an appropriate temperature to form a blue or black oxide layer on the surface, also known as bluing. This treatment not only enhances the corrosion resistance of the workpiece but also produces a smooth blackened layer that can achieve a glossy finish. The figure shows a component made of S45C with its surface after bluing treatment.

Phosphating is the process in which a workpiece is immersed in a phosphating solution, resulting in the deposition of an insoluble crystalline phosphate conversion layer on the surface. After phosphating, the pores are sealed to provide rust protection. The figure shows a component made of S45C with its surface after phosphating treatment.

Tool steel (SKD11, SK3, SKH51): These materials have moderate hardness. To further enhance their surface properties, such as wear resistance, lubricity, and anti-adhesion, they are often treated with titanium coatings (TiC, TiN), chrome plating, nickel plating, bluing, or polishing.

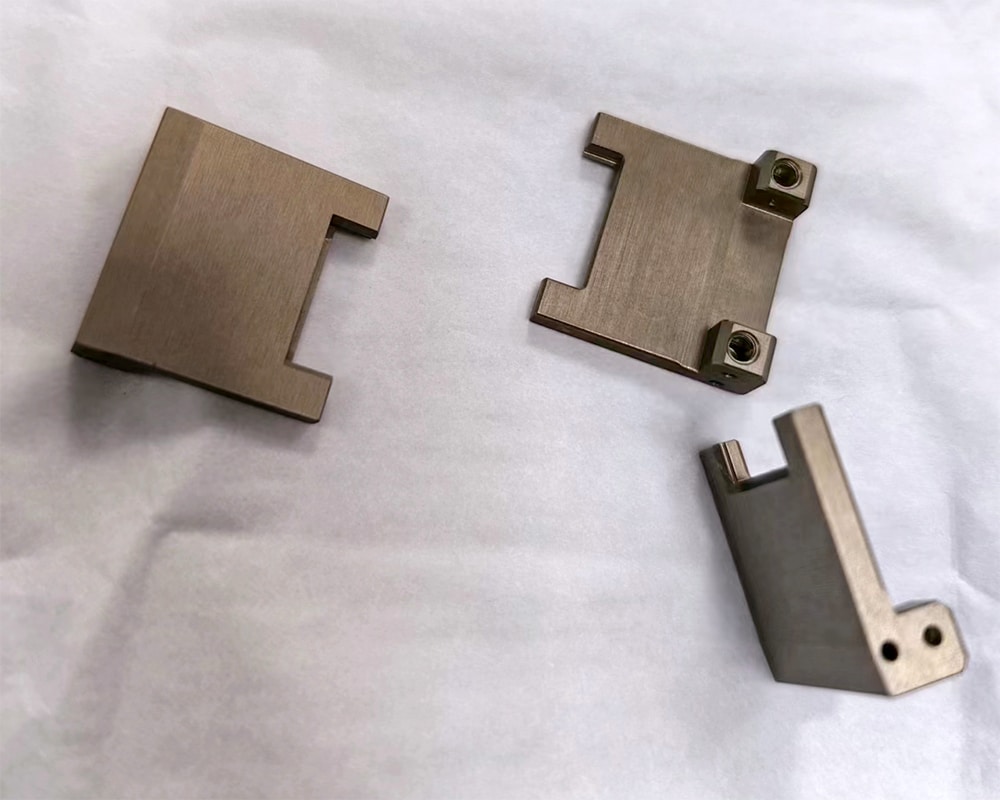

The figure shows a component made of SKD11 with its surface after nickel plating

The figure shows a component made of SKD11 with its surface after chrome plating.

Polishing is a finishing process used to refine the surface of a component. The figure shows a component made of SKD11 with its surface after mirror polishing.

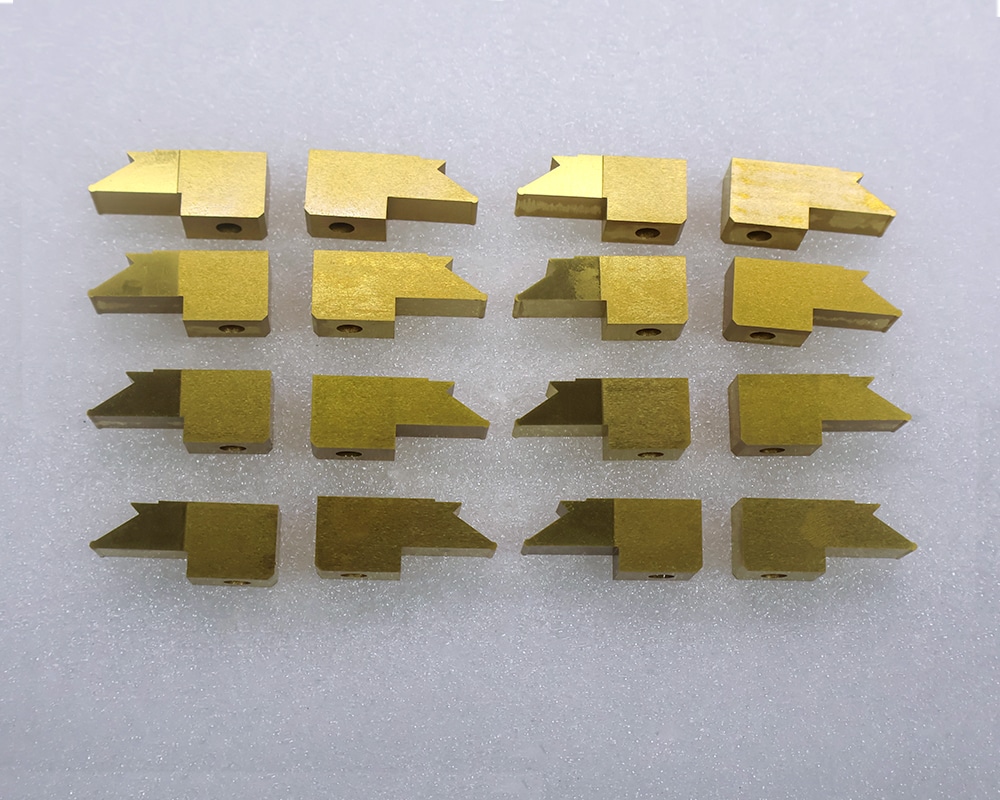

The figure shows a component made of SKD11 with its surface after low-temperature TiC coating.

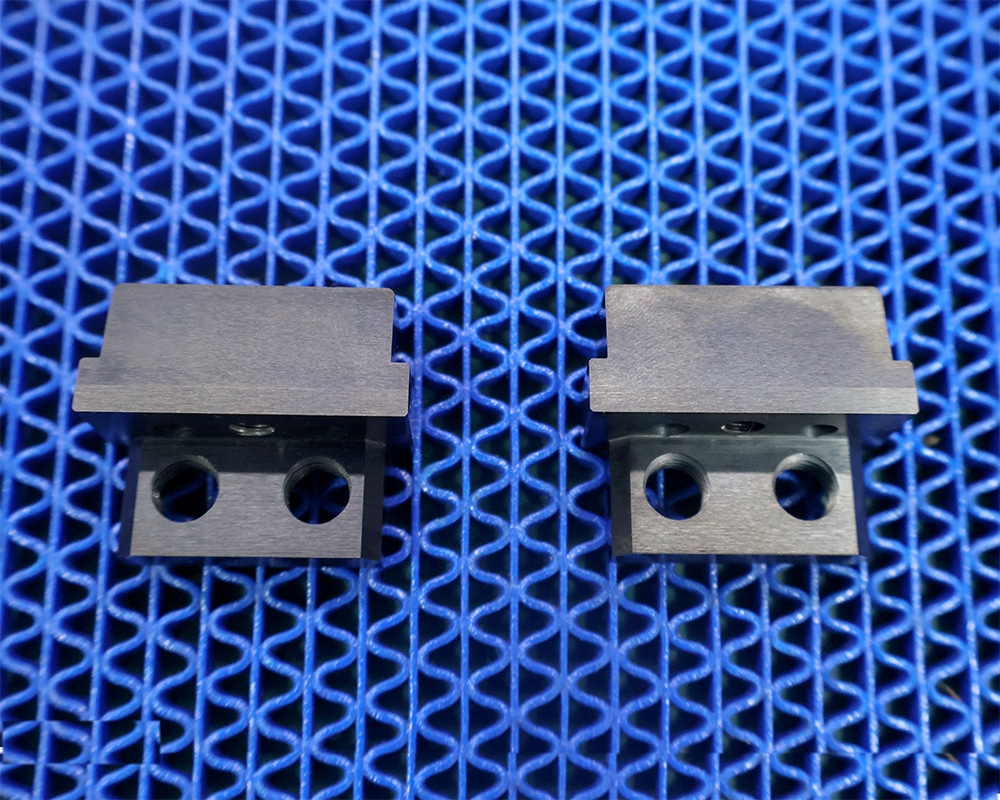

The figure shows a component made of SK3 with its surface after bluing treatment.

Titanium coating is primarily used to enhance the surface wear resistance of a workpiece. The figure shows a component made of SKH51 with its surface after titanium coating.

Plastic mold steel (NAK80): The surface of this material is prone to corrosion, so it is generally treated with hard chrome plating, nickel plating, nitriding, sandblasting, or polishing.The figure shows a component made of NAK80 with its surface after chrome plating and polishing.

Nickel plating is highly stable in air and can resist corrosion from atmosphere, alkalis, and certain acids. Its relatively high hardness also enhances the durability of wear-prone products. The figure shows a component made of NAK80 with its surface after nickel plating and polishing.

Sandblasting is mainly used to enhance a component’s mechanical strength, wear resistance, fatigue resistance, and corrosion resistance; it is also applied for surface matt finishing, removal of scale, and relieving residual stresses in cast, forged, or welded parts. The figure shows a component made of NAK80 after sandblasting treatment.

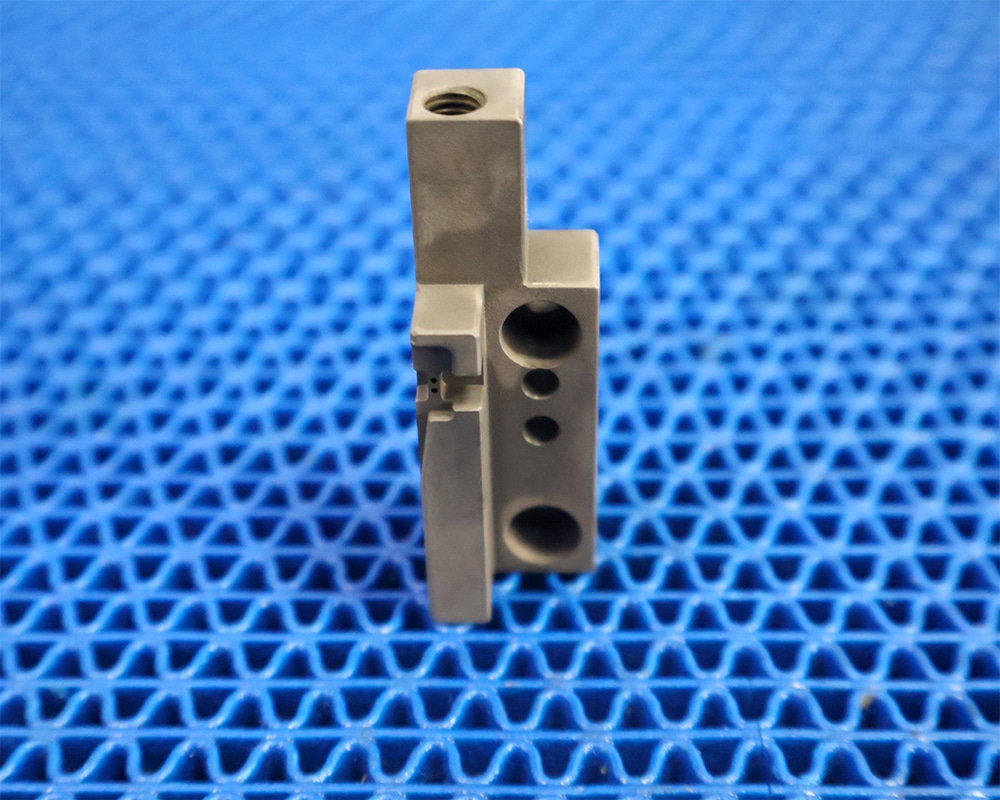

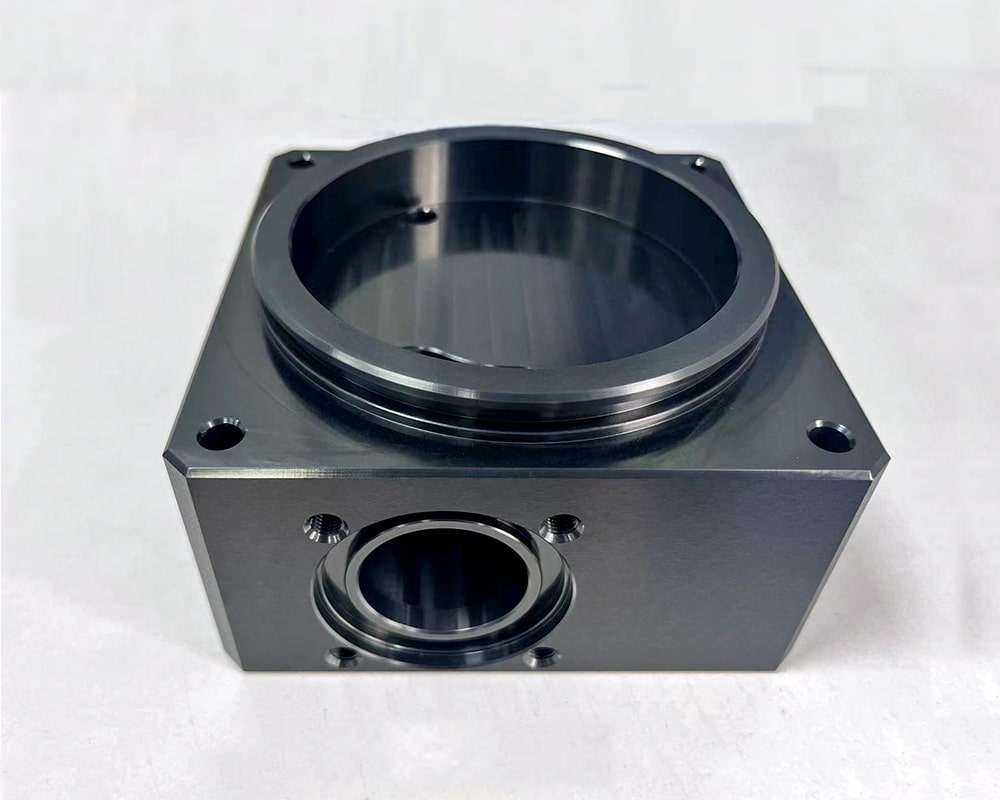

Aluminum parts (A2017, A6061): For aluminum alloys, anodizing or hard anodizing is commonly applied. Before anodizing, the parts undergo pre-treatments such as polishing, degreasing, and cleaning, followed by rinsing, coloring, and sealing.Anodizing is mainly applied to improve a component’s wear and corrosion resistance. The figure shows a component made of A2017 with its surface after hard gray anodizing.

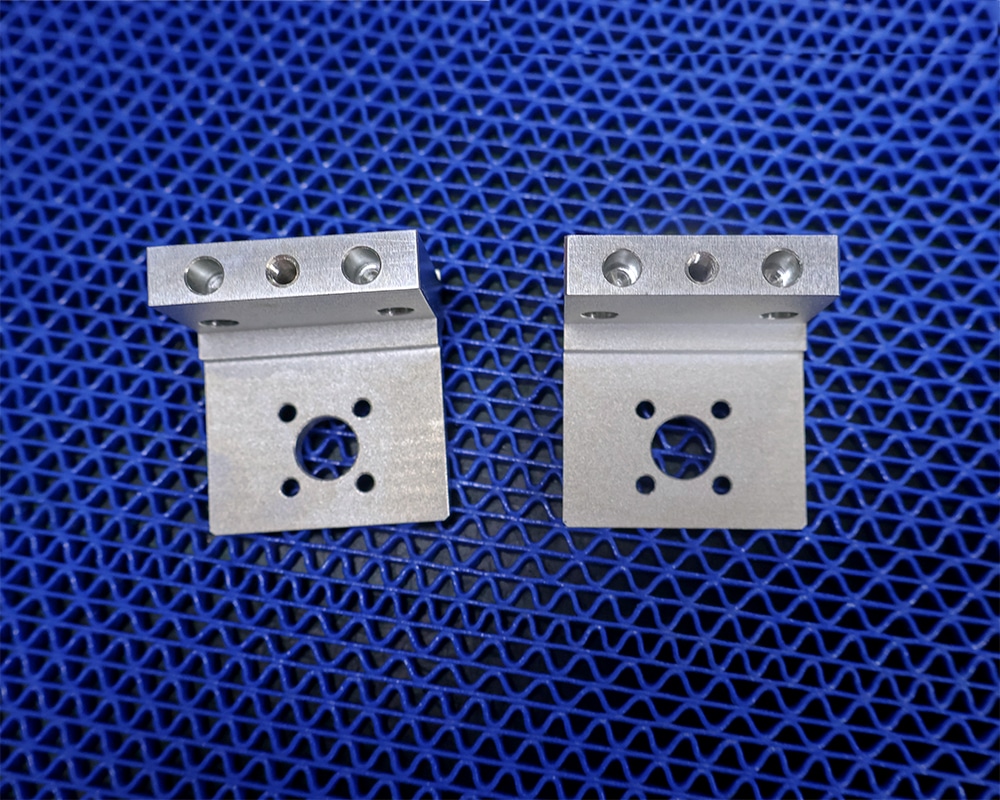

The figure shows a component made of A6061 with its surface after hard anodized white treatment.

The figure shows an aluminum part with its surface after black anodizing.

With a mature process system and professional equipment, our company masters a wide range of surface treatment technologies. Whether the goal is to enhance aesthetics, improve corrosion resistance, or boost mechanical performance, we can meet diverse product requirements through electroplating, chemical treatments, mechanical treatments, and other versatile techniques.Currently, our mature surface treatment processes cover the following categories:Electroplating: Zinc plating, Nickel plating, Chrome plating, Titanium coating

Chemical treatments: Anodizing, Bluing, Phosphating, Carburizing, Nitriding

Mechanical treatments: Sandblasting, Rolling, Polishing

High-performance coatings: TiAlN, TiAlCN, AlCrN, AlCrTiN, TiN, CrN, TiCN, DLC, PVD coatings