Metal Heat Treatment Process

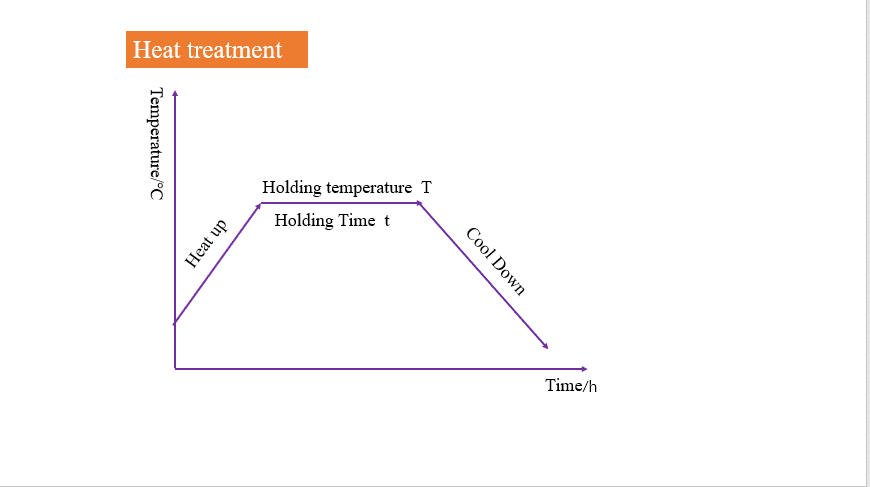

Heat treatment is a process in which the heating rate, soaking time, and cooling rate are carefully controlled to change the internal microstructure of metals, thereby adjusting their mechanical properties. The entire process can be divided into three stages.First, during the heating stage, it is crucial to control the heating method and pay attention to chemical reactions that may occur in the metal during heating. Therefore, a stable and reliable heating environment must be provided for the metal material.Second, in the holding stage, the holding temperature and time should be set according to the process requirements and kept stable to ensure a uniform transformation of the metal’s internal structure.Finally, in the cooling stage, appropriate cooling methods and durations should be selected based on the characteristics of different metals, so as to guarantee the desired final properties of the material.

Heat Treatment Process Diagram

Heat treatment is a commonly used method to improve the properties of metals. According to different processes and purposes, it can be mainly divided into three categories: overall heat treatment, surface heat treatment, and chemical heat treatment.

Overall heat treatment: This process involves heating and cooling the entire workpiece to change its internal structure and properties. It mainly includes annealing, normalizing, quenching, and tempering processes.

Surface heat treatment: This process only heats the surface layer of the workpiece. Common methods include flame hardening and induction heat treatment (high-frequency quenching).

Schematic Diagram of Hardness Testing for High-Frequency Quenched Workpiece (with Black Oxide Layer on Surface)

Chemical heat treatment: This process improves the performance of the workpiece by changing the chemical composition of its surface layer. Common methods include carburizing, nitriding, and carbonitriding.

Schematic Diagram of Hardness Testing for Carburized Workpiece

Next, we will focus on several processes involved in overall heat treatment.

Annealing involves heating a metal material to near or below its phase transformation temperature, holding it for a sufficient time, and then cooling it slowly, such as furnace cooling or burying in sand. This process effectively relieves internal stresses in the workpiece, preventing deformation or cracking during subsequent processing or use.

Similar to annealing, normalizing is also a common heat treatment process. It involves heating the metal above its transformation temperature, holding it for a period to allow complete austenitization, and then cooling it naturally in air. Normalizing helps refine the grain structure and homogenize the microstructure, thereby improving toughness and fatigue resistance without reducing the material’s hardness, ultimately enhancing the overall mechanical properties of the material.

Both annealing and normalizing belong to the “softening” category of heat treatment processes, but the cooling rate in normalizing is generally faster than in annealing.

On the other hand, quenching involves heating the metal above its transformation temperature, holding it to form a uniform austenite, and then rapidly cooling it in a medium such as water or oil. Quenching can significantly increase the hardness and strength of the material, but it can also induce higher internal stresses and make the material more brittle. Therefore, tempering is often performed after quenching.

Tempering refers to reheating a quenched workpiece to below the AC1 temperature, holding it for a certain period, and then air-cooling it to room temperature. This process effectively relieves the internal stresses induced by quenching and improves the material’s toughness and service safety.

Quenching and tempering belong to the “hardening” category of heat treatment processes. They form an inseparable combination: quenching hardens the material, while tempering adjusts its properties and reduces brittleness.

Heat treatment is a key technology for controlling the properties of metal materials, primarily affecting their microstructure evolution, mechanical properties, and residual stresses. Let’s take a closer look at how each of these aspects changes.

First, heat treatment can significantly alter the internal microstructure of a material, mainly in three aspects: grain size, phase composition, and precipitates.

Grain size: Fine and uniform grains can improve both the strength and toughness of a material, whereas coarse grains tend to degrade its performance.

Phase composition: The distribution and proportion of different phases directly affect the material’s hardness, strength, and toughness.

Precipitates: These tiny secondary phase particles, along with their morphology and distribution, have a significant impact on the material’s strength and wear resistance.

Secondly, by controlling the microstructural features mentioned above, heat treatment can optimize the material’s mechanical properties:

Hardness: Reflects the material’s resistance to local deformation and is often adjusted through quenching and tempering processes.

Strength: The ability of a material to resist fracture, which can be adjusted through mechanisms such as grain refinement strengthening, solid-solution strengthening, and precipitation strengthening.

Toughness: The ability of a material to absorb energy and resist fracture, which is usually improved by grain refinement and adjustment of phase composition.

In addition, temperature differences between the surface and the core during heat treatment can generate residual stresses. If not properly controlled, these stresses may affect the dimensional stability and service life of the part.

In summary, heat treatment precisely controls microstructural changes to achieve an optimal balance among hardness, strength, toughness, and stress state, thereby meeting the performance requirements of various application scenarios.

Schematic Diagram of Hardness Testing for Cryogenically Treated Workpieces

We not only provide comprehensive overall heat treatment services, but have also established a professional process matrix covering key technologies such as high-frequency (localized) quenching, vacuum heat treatment, High frequency induction hardening, cryogenic treatment, and carburizing. Through precise process control, we ensure that every product achieves the desired superior performance — safeguarding the quality you can rely on.