Japanese Mitutoyo Precision Measuring Instruments

Mitutoyo (Japan)

Mitutoyo Corporation is a world-leading manufacturer of precision measuring instruments, founded by Yehan Numata in 1934 in Kawasaki, Kanagawa, Japan. Mitutoyo emphasizes that measurement is the foundation of quality, believing that only through reliable measurement can quality be ensured and technological progress be achieved. As global manufacturing moves toward intelligent production, Mitutoyo is dedicated to integrating traditional precision tools with digital measurement technologies, providing comprehensive solutions that extend from “measurement” to “quality management.” Since its establishment, the company has focused on the field of high-precision dimensional measurement, driving the transformation of manufacturing from traditional mechanical instruments to intelligent, digital measurement systems.

Introduction to Mitutoyo Micrometers

A micrometer, also known as a micrometer screw, is a precision measuring instrument that offers higher accuracy than a vernier caliper. It can achieve a measuring accuracy of ±1 μm with a resolution of 0.001 mm. Our company is equipped with a wide range of micrometers, including inside micrometers, outside micrometers, and digital indicators. Below is an introduction to the Mitutoyo series of measuring instruments.

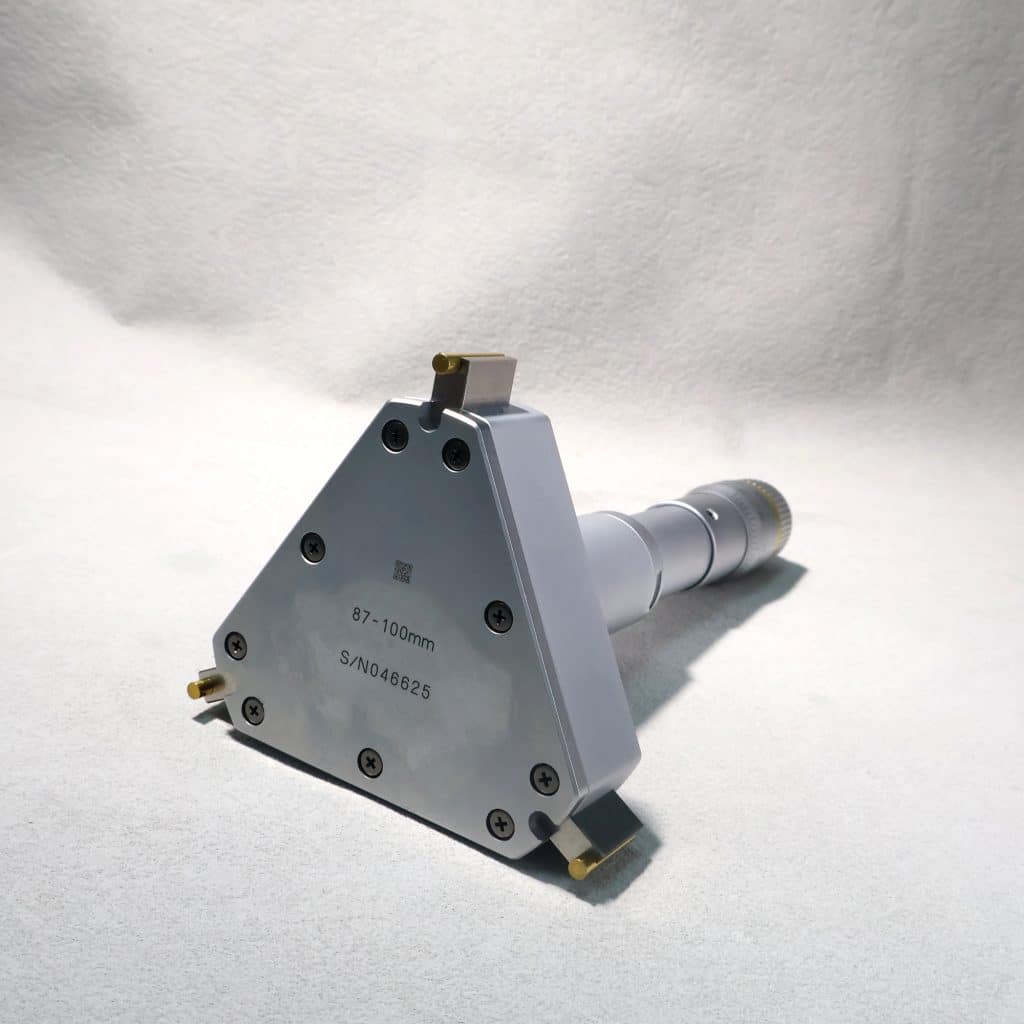

The Mitutoyo 368-173 is a three-point inside micrometer from Mitutoyo’s Holtest Series. An inside micrometer is a high-precision instrument used for measuring internal diameters. Mitutoyo’s Holtest Series (three-point inside micrometers) features a self-centering, three-point contact design, providing accurate and stable measurements. These instruments are widely used for precision internal bore inspection in industries such as machining, mold making, automotive, and aerospace.

A Mitutoyo Holtest three-point inside micrometer mainly consists of the following components:

Measuring Head: Contains three measuring anvils evenly spaced at 120°, forming the three-point measurement.

Spindle and Screw Mechanism: Similar to an outside micrometer, it features a precision screw inside. When the sleeve is rotated, the measuring anvils expand or contract evenly.

Ratchet or Force-Limiting Device: Ensures a consistent measuring force with each measurement, preventing excessive manual pressure that could cause dimensional errors.

Reading Device: Available in mechanical scale or digital display types, with typical accuracy of 0.001 mm or 0.005 mm.

Positioning Structure / Connecting Rod: For measuring deep or large bores, an extension rod can be added.

Mitutoyo Three-Point Measurement Principle

When the operator rotates the threaded sleeve, the internal spindle drives the three measuring anvils to expand evenly in the radial direction. The three anvils make 120° symmetrical contact with the bore wall. When the ratchet clicks, it indicates that the measuring force has reached the standard value. Reading the mechanical scale or digital display then gives the diameter of the bore.

The Holtest three-point micrometer offers distinct advantages.

In a traditional two-point measurement structure, manual centering is often required, which can easily lead to measurement errors. In contrast, the three-point measurement structure features three anvils symmetrically spaced at 120°, forming a stable three-point support that automatically aligns with the bore axis, eliminating eccentricity errors.

The Mitutoyo 368-173 three-point inside micrometer uses a high-precision differential screw independently developed by Mitutoyo. Each rotation of the screw provides an extremely uniform feed, ensuring that the radial displacement of the measuring anvils corresponds perfectly to the scale reading. Mechanical and pitch errors are controlled within micron-level tolerances.

The force-limiting ratchet device automatically applies a consistent measuring force for each measurement, eliminating variations caused by manual pressure. This prevents elastic deformation or frictional sticking of the bore walls, ensures uniform measuring force, and improves repeatability and measurement accuracy.

The three measuring anvils are made of special materials with a titanium nitride (TiN) coating, offering high hardness, excellent wear resistance, and low friction. This ensures that the anvils maintain their geometric accuracy over long-term use, preventing measurement errors due to wear, and providing high stability and durability.

The main structural components are made of stainless steel or nickel-alloyed steel and undergo heat treatment and stabilization, which tightly controls the coefficient of thermal expansion under stable environmental conditions (20 ± 1 °C). The measuring surfaces and screw mechanism are low-stress ground and carefully calibrated, ensuring thermal stability.

Mitutoyo Digital Outside Micrometer 293-231-30

The Mitutoyo digital outside micrometer is a micrometer produced by Mitutoyo. Unlike an inside micrometer, an outside micrometer is primarily used to measure the external diameter, thickness, or outer dimensions of a workpiece.

The Mitutoyo digital outside micrometer is available in multiple standard ranges, including 0–25 mm, 25–50 mm, and 50–75 mm, meeting various dimensional measurement needs. Its compact structure mainly consists of a frame, anvil, micrometer spindle, thimble, sleeve, force and locking device.

The spindle and anvil clamp onto the workpiece surface, and their measuring faces are typically made of tungsten carbide, also known as hard alloy. The tungsten carbide faces are fixed to the spindle and anvil ends through high-temperature brazing or press-fitting, and then precision-ground to ensure flatness and smoothness. This guarantees the accuracy and repeatability of the outside micrometer over long-term use. Tungsten carbide is an excellent material for measuring instruments due to its high hardness and wear resistance.

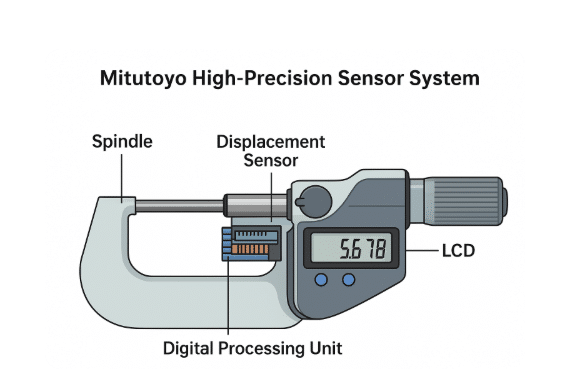

the principle diagram of Mitutoyo’s high-precision sensing system.

The gauge features Mitutoyo’s high-precision sensing system, offering a resolution of up to 0.001 mm or 0.00005 inch. Its operation relies on detecting minute spindle displacements via a linear encoder or capacitive/magnetic sensor. The electronic system converts these displacements into digital signals, which are displayed on the LCD screen. This sensing system ensures high accuracy and excellent repeatability, provides a direct digital readout to minimize human error, and supports data management.

Mitutoyo Digital Indicator

The Mitutoyo digital indicator is a high-precision measuring instrument used for detecting dimensional deviations, geometric errors, or comparative measurements. It accurately measures the minute displacement of the probe through its built-in ABSOLUTE encoder sensing system and displays the results in digital form on the LCD screen.

The Mitutoyo digital indicator achieves extremely high resolution—up to 0.001 mm or even 0.0005 mm—primarily due to the advanced design of its internal sensing system and structural configuration.

It uses a high-performance ABSOLUTE encoder system, which is a core Mitutoyo technology. As the spindle moves, the system precisely detects displacement using a high-density optical or electromagnetic grating. The grating lines are extremely fine, reaching micron-level spacing, allowing even the smallest movements to be accurately recognized. Compared with traditional incremental encoders, it does not require repeated zeroing, offers more stable signal transmission, and has stronger resistance to interference. This ensures that the measurement signals are highly precise and reliable, with digital readouts accurate to 0.001 mm.

The probe and guiding mechanism are manufactured using ultra-precision grinding and fitting processes, resulting in minimal friction. Tv he internal ball or sliding components are of extremely high accuracy, ensuring that the probe moves smoothly without vibration. This mechanical stability allows for more precise detection of minute displacements.

It features a high-sensitivity signal acquisition and electronic processing circuit. The electronic system uses a high-resolution analog-to-digital conversion (ADC) chip to accurately convert minute electrical signal changes into digital values. The circuit also includes signal amplification and filtering, effectively reducing noise interference. As a result, the measurements are not only high-resolution but also exhibit excellent repeatability and strong stability.

Low thermal expansion materials are used in critical components, along with a temperature compensation algorithm, effectively preventing environmental fluctuations from affecting the resolution and measurement accuracy.

Our company is equipped with a wide range of Mitutoyo measuring instruments. During the manufacturing process, we monitor the precision of workpieces in real time, improve work efficiency, and implement digital management. This ensures that we deliver consistently high-quality products with reliable dimensional data, meeting the highest standards for our customers.