Hastelloy

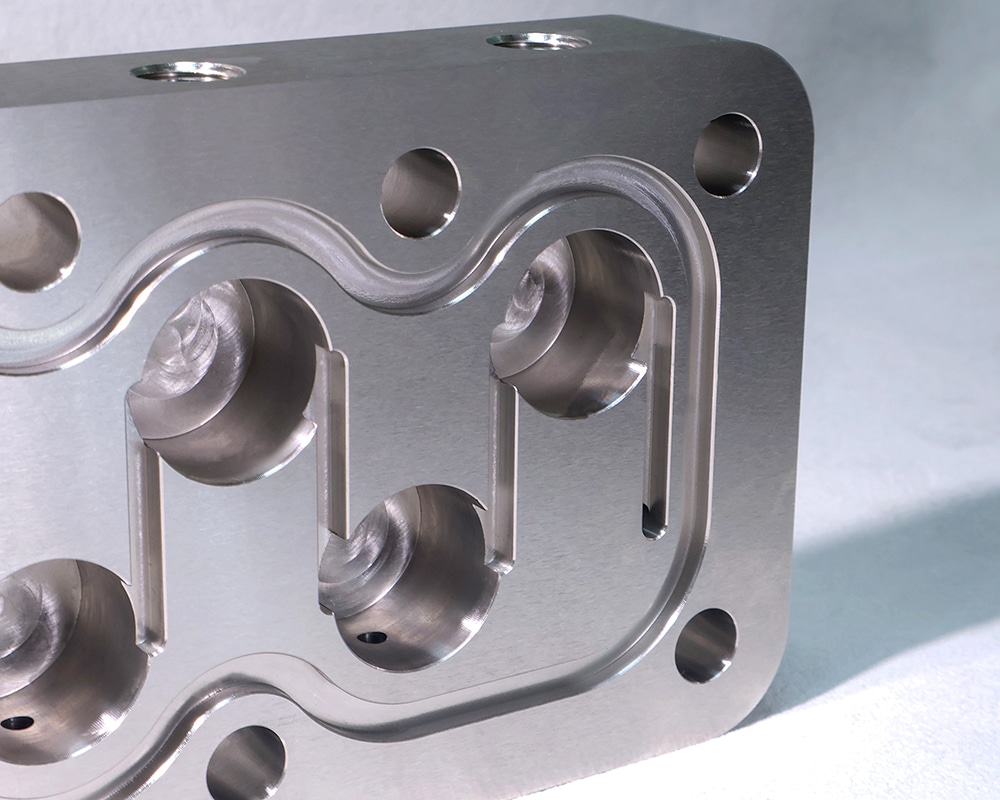

The illustration shows one of our core components — Hastelloy C-276 chemical vessel parts, specially designed and manufactured for harsh and highly corrosive environments.

Hastelloy C-276, known as the “King of Corrosion-Resistant Alloys,” is a wrought, improved version of Hastelloy C developed by Haynes International in 1968. It has been widely used in highly corrosive environments. To provide a comprehensive understanding of its overall characteristics, this article systematically analyzes the material properties of Hastelloy C-276 from several perspectives, including its chemical composition, corrosion resistance, mechanical properties, processing technology, and typical applications.

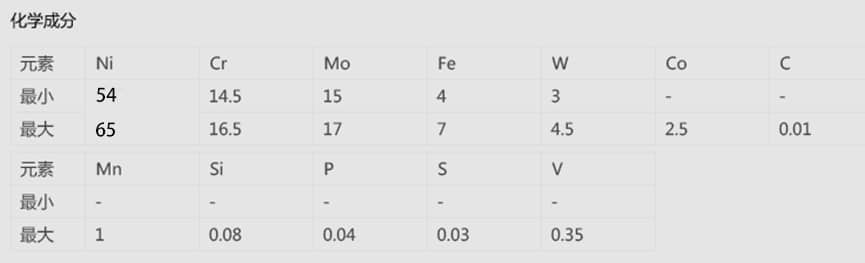

Chemical Composition

Hastelloy C-276 is a high-performance nickel-based superalloy, renowned for its outstanding corrosion resistance and high-temperature stability in extreme environments. The realization of these exceptional properties fundamentally stems from its carefully engineered chemical composition. The specific chemical composition of Hastelloy C-276 is shown in the table below.

Corrosion Resistance

Hastelloy C-276 exhibits excellent corrosion resistance in a wide range of harsh environments, making it suitable for acidic media, chloride-containing conditions, and processes involving mixed acids and impurities.In terms of acidic media, Hastelloy C-276 demonstrates excellent resistance to reducing acids such as hydrochloric acid, sulfuric acid, and phosphoric acid. It can also withstand oxidizing acids like nitric acid; however, it is at high concentration that it should be used.In chloride-containing environments, Hastelloy C-276 exhibits excellent resistance to chloride stress corrosion cracking, making it highly suitable for seawater or media containing chloride ions. In addition, its localized corrosion resistance is outstanding, particularly in environments with halide ions, effectively preventing pitting and crevice corrosion.In more complex environments containing mixed acids and impurities, such as oxidizing ions like Fe³⁺ and Cu²⁺, the alloy still maintains stable corrosion resistance.It should be noted that Hastelloy also has its limitations. It is not recommended for use in concentrated hot sulfuric acid or high-temperature hydrofluoric acid environments, where its corrosion resistance may not meet the required performance.

Mechanical Properties

Hastelloy C-276 exhibits excellent mechanical properties across a wide temperature range.

Room Temperature Properties: Under ambient conditions, Hastelloy C-276 typically exhibits the following mechanical properties: tensile strength of approximately 690 MPa, yield strength of around 283 MPa, and elongation of about 40%.

High-Temperature Properties: As the temperature increases, the tensile strength and yield strength of Hastelloy C-276 gradually decrease, but it still maintains good overall performance. For example, at 500°C, the tensile strength is approximately 550 MPa, the yield strength decreases to 240 MPa, and ductility improves. At 800°C, the tensile strength drops to around 400 MPa, while the yield strength decreases to about 150 MPa. This change is primarily due to lattice expansion and enhanced grain boundary slip at high temperatures; however, Hastelloy C-276 still retains excellent toughness and oxidation resistance in high-temperature corrosive environments.

Low-Temperature Properties: At extremely low temperatures, Hastelloy C-276 does not exhibit embrittlement; instead, it shows increased strength and good toughness. For example, at -100°C, the tensile strength is approximately 780 MPa, the yield strength is 310 MPa, and ductility remains at a high level. At -196°C, the tensile strength can even rise above 850 MPa. This characteristic gives Hastelloy C-276 significant potential for applications in low-temperature storage equipment and deep-sea environments.

In summary, Hastelloy C-276 exhibits high tensile strength and good ductility across a wide temperature range from low to high temperatures, making it an indispensable material for applications in corrosive environments and extreme temperature conditions.

Processing Technology

Hastelloy C-276 exhibits high work-hardening tendency and is considered difficult to machine in CNC operations, often causing rapid tool wear and machining hardening. To ensure machining quality and efficiency, it is essential to select appropriate cutting tools and set optimal cutting parameters. During machining, adequate cooling and lubrication should be maintained, and stable, uniform cutting loads along with proper tool path planning should be employed to prevent vibration and overheating, thereby effectively controlling work hardening and tool wear.

A high-strength Hastelloy workpiece is undergoing precision milling on a CNC machine to achieve its final design geometry and meet stringent dimensional tolerances.

As a typical difficult-to-machine material, Hastelloy C-276 is highly susceptible to workpiece burn or micro-cracking due to grinding heat during the grinding process. Therefore, strict control of process conditions is essential. To effectively suppress grinding temperature, it is necessary to select abrasive wheels with appropriate characteristics and adopt specific combinations of process parameters, carefully balancing wheel speed, feed rate, and depth of cut. Throughout the grinding process, adequate cooling and efficient heat dissipation are especially critical. It is generally recommended to use high-flow, high-pressure cooling with filtration systems, maintain the wheel in good condition, and monitor sparks and sound changes to assess the machining status in real time, thereby avoiding material damage.

The Hastelloy workpiece is undergoing high-precision grinding to achieve strict dimensional tolerances and surface roughness requirements.

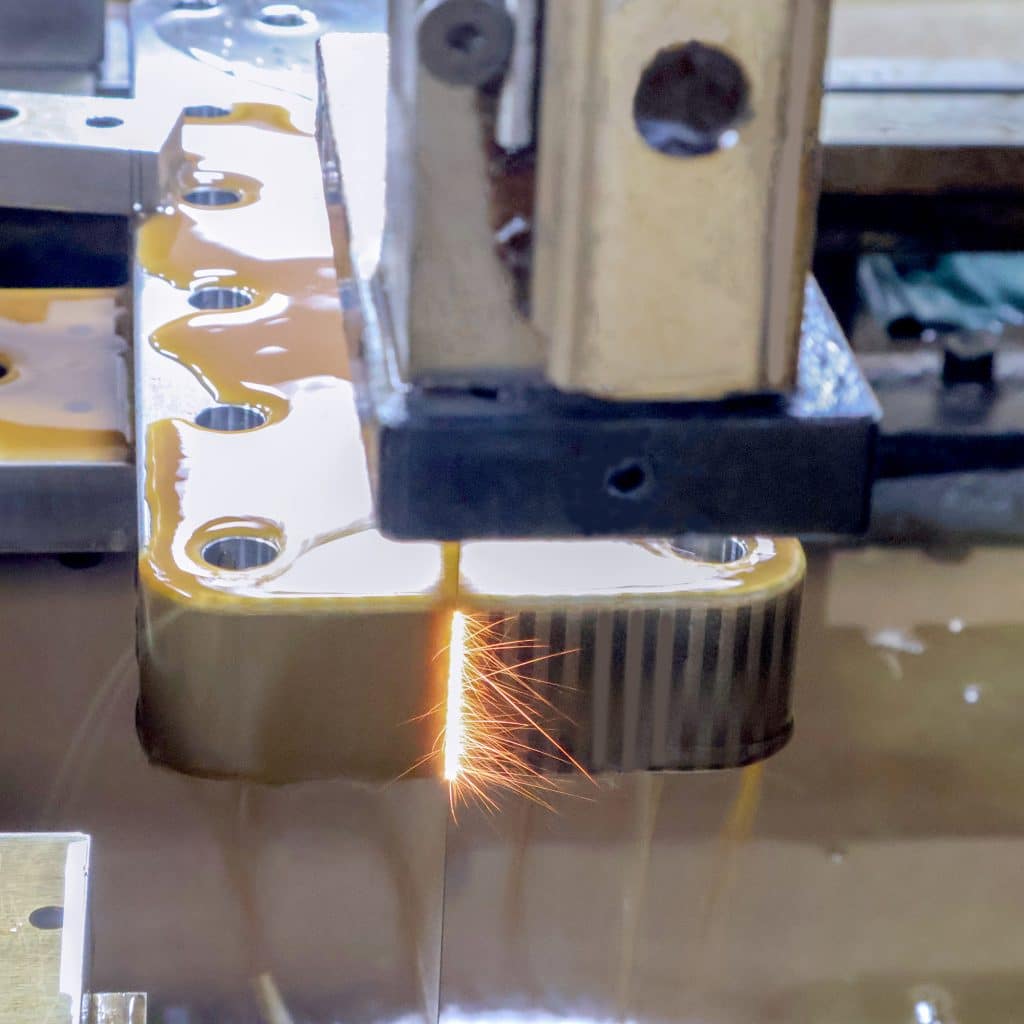

During wire-cut EDM machining of Hastelloy C-276, its poor thermal conductivity and tendency to overheat make process control challenging, often resulting in the formation of recast layers and micro-cracks. Therefore, it is essential to adopt specialized process settings and control strategies, properly configure electrical parameters and tool paths, and ensure effective inter-electrode cooling and chip removal. These measures help minimize thermal effects and maintain the integrity of the machined surface.

Wire-cut EDM machining of Hastelloy C-276 components (the right side of the part shows the roughing marks from the first cut, while the left side shows the final surface from the second finishing pass).

Main Application Areas

Thanks to its excellent corrosion resistance, high-temperature stability, and high purity, Hastelloy C-276 plays a key role in multiple industrial sectors. It is commonly used in the following application areas:

Chemical Equipment: Frequently used in the manufacture of reactors, heat exchangers, and distillation columns, especially suitable for handling corrosive media containing chloride ions.

Oil and Gas: In oil and gas extraction, Hastelloy C-276 is used for pipelines and environments exposed to acidic gases, effectively resisting corrosion from sulfides and carbon dioxide.

Environmental Engineering: Widely used in flue gas desulfurization systems and wastewater treatment equipment, Hastelloy C-276 can maintain stable operation in harsh chemical environments.

Pharmaceutical and Food Industries: Suitable for high-purity reaction vessels, Hastelloy C-276 meets strict requirements for low metal ion release, ensuring the purity and safety of products.

Nuclear Industry: Applicable in facilities such as nuclear waste treatment, Hastelloy C-276 offers excellent radiation resistance and can maintain the structural integrity of the material over extended periods.

Thanks to its outstanding performance and broad application prospects, Hastelloy is gradually becoming an indispensable star in the industrial sector. The key to realizing its value lies in choosing a partner who truly understands its machining characteristics—and this is precisely the core value we offer.

We maintain a comprehensive stock of Hastelloy raw materials throughout the year and leverage our advanced precision machining capabilities to transform high-quality materials into high-precision critical components. Our machining facilities are equipped with high-performance milling machines from brands such as Okuma and Mazak, Western wire-cut EDM, BaQi wire-cut EDM, and precision grinders, enabling ±0.005 mm machining accuracy and Ra 0.4 μm surface roughness, fully meeting stringent quality requirements.

We are well aware of the challenges involved in machining Hastelloy. Drawing on years of practical experience, our technical team possesses in-depth knowledge of its machining behavior, particularly in optimizing milling and grinding parameters, and can scientifically tailor the process according to material condition and part requirements. From material selection and process optimization to finished product delivery, we provide a truly professional, one-stop solution for your Hastelloy components.