Demagnetizing process for parts

In the field of machining, some parts require demagnetization treatment after processes such as cutting and grinding. This necessity arises from the complex interaction between materials science and magnetic field theory. Simply put, demagnetization is performed to prevent potential issues during subsequent use by eliminating or reducing the residual magnetism generated within the workpiece during manufacturing.

Let’s take a closer look at what residual magnetism is.

Residual magnetism, also known as residual magnetic induction or residual magnetization, refers to the phenomenon where a workpiece retains a certain level of magnetism even after the external magnetic field, electric current, or mechanical force has been removed. Although this magnetism is usually weak, it can still have a noticeable impact on product quality, measurement accuracy, and subsequent manufacturing processes in the field of precision machining.

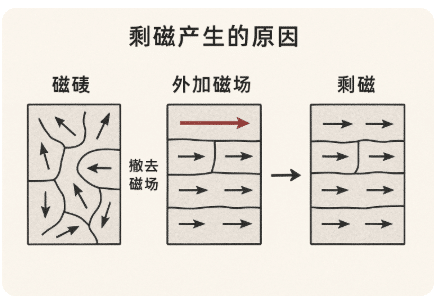

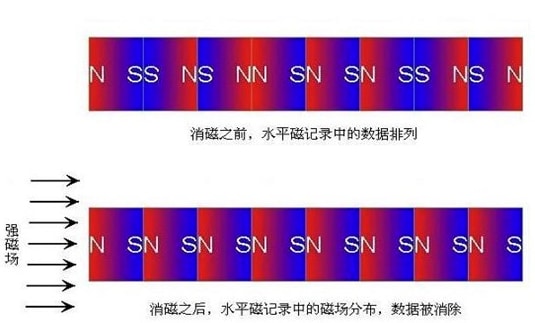

The generation of residual magnetism originates from the internal structure of magnetic materials, which are composed of numerous microscopic regions called magnetic domains. Within each domain, the electron spins are aligned in the same direction, effectively forming tiny magnets.When the material is in an unmagnetized state, the orientations of these domains are random, resulting in no overall magnetism or only weak magnetism. When the material is exposed to an external magnetic field, the domains begin to gradually reorient themselves, tending to align with the direction of the applied field. As a result, the overall magnetic induction of the material increases.If the external magnetic field is strong enough and applied for a sufficient period, nearly all magnetic domains will align in the same direction, and the material becomes fully magnetized. However, once the external field is removed, due to factors such as interactions between domains, crystal structure, and magnetic anisotropy, some domains do not immediately return to their original random orientations but remain partially aligned. This retained alignment gives rise to residual magnetism.

Residual magnetism does not alter the dimensions or structure of a workpiece, but in precision manufacturing, it may lead to a series of undesirable consequences. Next, let’s discuss the situations in which demagnetization treatment is required.

If a workpiece is not sufficiently demagnetized, it can attract ferromagnetic materials—this is often used as a simple way to check whether demagnetization has been successfully performed. Workpieces that have not undergone demagnetization tend to attract iron chips or abrasive particles during use, which can negatively affect surface roughness and tool life during subsequent machining processes. Therefore, demagnetization is necessary.In the aerospace industry, the cosmic magnetic field is one of the environmental factors affecting spacecraft in orbit. During manufacturing and assembly, spacecraft components may possess varying degrees of magnetism. The cosmic magnetic field can exert magnetic forces on these components, potentially disrupting the operation of critical systems and affecting the overall magnetic characteristics of the spacecraft. This can have serious implications for flight safety and mission performance, making demagnetization an essential step in spacecraft manufacturing.Additionally, coating thickness is one of the most important parameters determining coating performance, directly influencing corrosion resistance, hydrogen embrittlement, and other quality characteristics. For components used in high-precision fields such as aerospace and medical devices, strict uniformity of coating thickness is required. However, residual magnetism within the workpiece can interfere with coating uniformity and thickness, which is another reason why demagnetization is necessary.

How is residual magnetism in a workpiece measured after demagnetization? And what are the acceptance standards for residual magnetism levels in a qualified workpiece?

-1024x1024.jpg)

A residual magnetism tester, also known as a Tesla meter, is a magnetic sensor based on a Hall-effect device. It is used to measure the magnetic field strength on a workpiece and the level of residual magnetism after demagnetization. This instrument is widely used in laboratories for the quantitative measurement of magnetic field leakage strength. In general, the demagnetization acceptance criterion is that the residual magnetic field should be below 0.5 mT.

If demagnetization is insufficient, the measured residual magnetism of the workpiece will be greater than 0.5 mT.

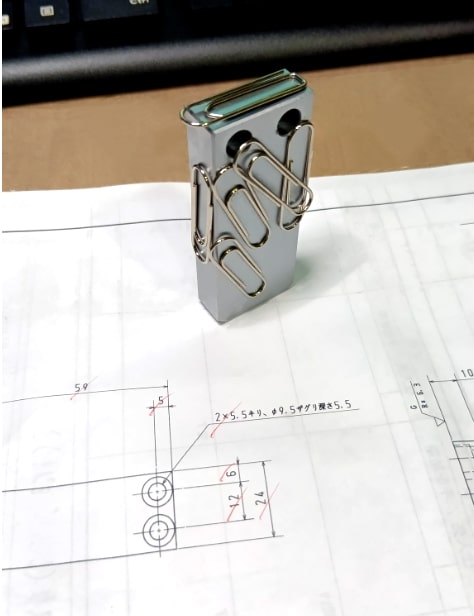

For a workpiece that is insufficiently demagnetized, a paperclip will strongly stick to its surface.

So, how can demagnetization be performed? At present, there are several methods available to achieve this.

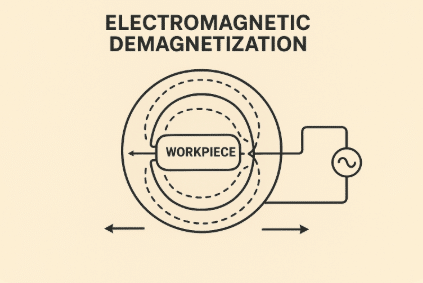

Electromagnetic induction demagnetization device: A demagnetizer is a specialized piece of equipment used to eliminate residual magnetism in objects. To demagnetize a workpiece, the demagnetizer applies an alternating magnetic field or a DC inversion principle to the magnetized metal component, weakening or completely removing its magnetism.When the electromagnetic induction demagnetization device is powered on, it generates an alternating magnetic field through its coils. This field induces eddy currents on the surface of the material, causing the magnetic domains inside the material to gradually rotate and return to a neutral equilibrium state, thereby achieving demagnetization.

Pulse magnetization demagnetization device: A pulse magnetization demagnetizer generates a strong pulsed magnetic field over a short period, causing the magnetic domains within the material to move vigorously, thereby achieving demagnetization.The effectiveness of this method depends on factors such as pulse frequency and magnetic induction strength.

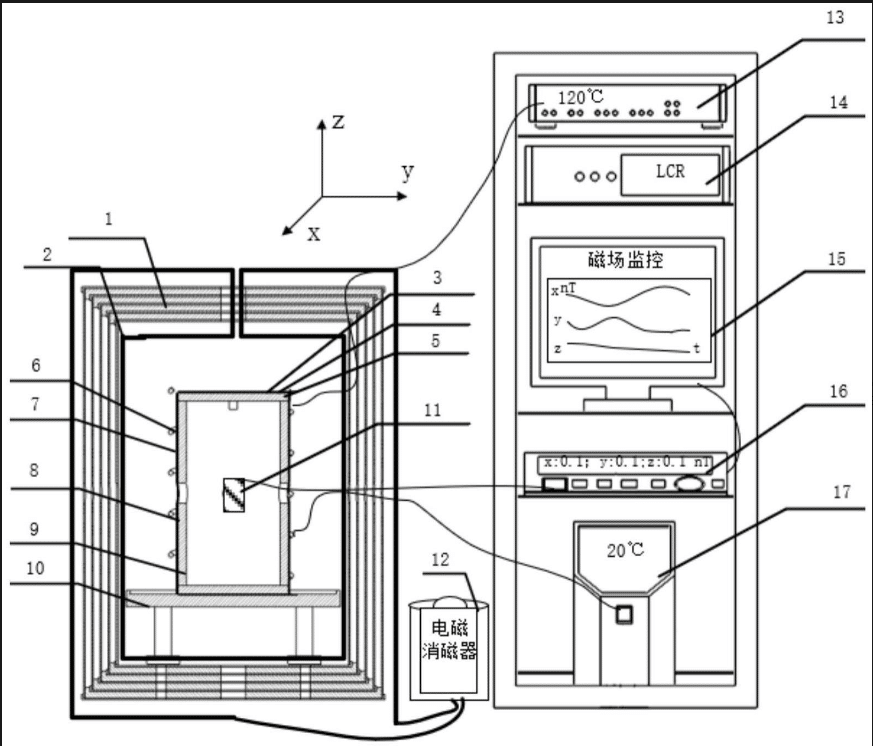

Thermal demagnetization device: A thermal demagnetizer eliminates magnetism by heating the material, causing the magnetic domains inside to lose their alignment. The effectiveness of this method is influenced by factors such as heating temperature and heating duration.

Although demagnetization may seem to increase production complexity and cost, in the long run it ensures product quality and performance. For workpieces with high precision requirements, demagnetization is a crucial step.

Fenghe has been deeply engaged in the precision machining industry for over twenty years. With a wide range of machining equipment, we are able to meet diverse customer requirements and deliver high-quality products.