Classification of Materials and Principles of Their Selection

Definition of Materials

Materials are substances with specific properties and structures that can fulfill one or more functional requirements. They serve as the fundamental basis for manufacturing products and building infrastructure, characterized by distinct physical, chemical, mechanical, electrical, thermal, optical, and acoustic properties. From the Stone Age and Bronze Age to the Iron Age, the evolution of materials has been closely intertwined with the development of human civilization. In modern times, materials science not only focuses on the fundamental characteristics of materials but also strives to drive technological advancement and social progress through research and development.

Macroscopic Classification of Materials

According to their core applications and performance characteristics, materials can be classified into five major categories.

Structural Materials: Focused on mechanical properties, these materials are used for bearing loads and providing support. Examples include construction steel, titanium alloys for aerospace, and high-strength steels in engineering machinery.

Electronic and Information Materials: Serving as the foundation of the electronics industry and information technology, such materials include semiconductor wafers, photoresists, conductive silver pastes, and optical fiber materials.

Energy Materials: Focused on the production, storage, and conversion of energy. Examples include photovoltaic cell materials, lithium battery materials, and fuel cell materials.

Biomedical Materials: Used in the medical field, these materials must possess biocompatibility. Examples include artificial joints, cardiac stents, and biodegradable sutures.

Aerospace Materials: Required to maintain stable performance under extreme conditions. Examples include high-temperature alloys for engines, carbon fiber composites for satellites, and thermal protection materials for spacecraft.

Detailed Classification of Metallic Materials

As the most important structural materials, metals can be subdivided into four major categories.

Ferrous Metals: Primarily referring to iron, chromium, manganese, and their alloys, with iron-carbon alloys (i.e., steel) being the most common. The name originates from the fact that steel often has a black Fe₃O₄ oxide layer on its surface, and manganese and chromium are frequently used to produce alloy steels with iron. Therefore, manganese and chromium, together with iron, are collectively referred to as ferrous metals. This category can be further subdivided into pig iron, ferroalloys, cast iron, as well as structural steel, tool steel, special steel, and cast steel.

Non-ferrous metal materials: All metals and their alloys other than ferrous metals. Common examples include titanium alloys, cast aluminum, cast zinc alloys, pure aluminum, zinc white copper, bronze, pure copper, and brass.

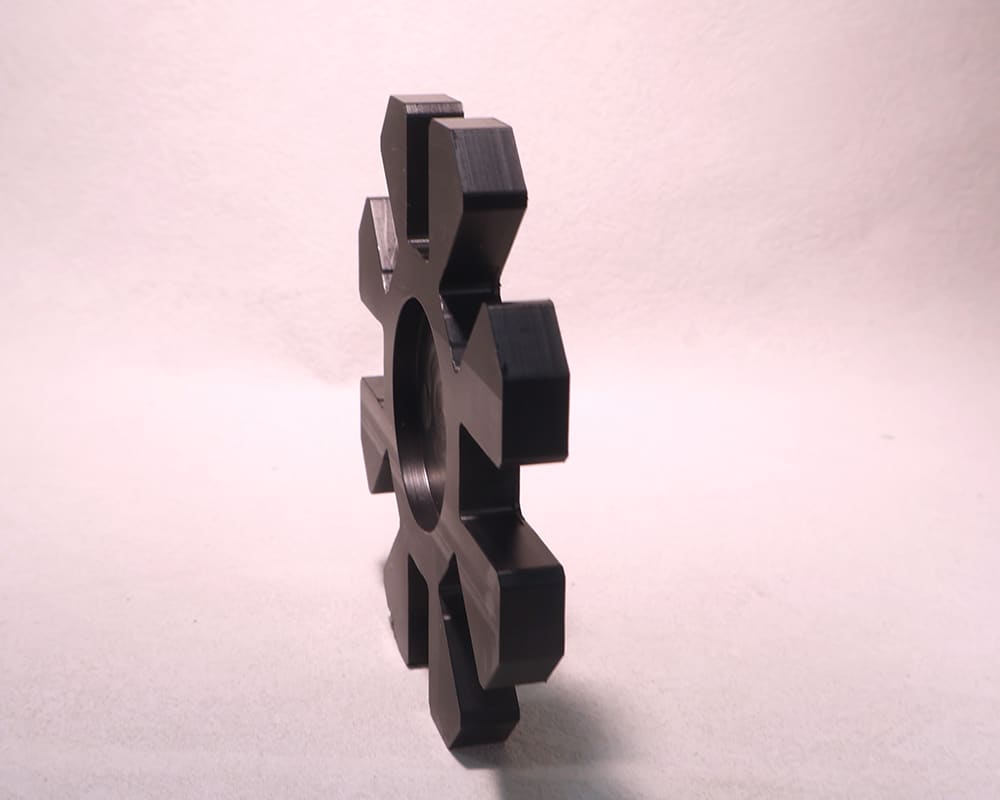

Composite Materials: New materials formed by combining two or more different materials through physical or chemical methods. For example, metal matrix composites, which use metal as the matrix and incorporate reinforcement phases such as ceramic particles or fibers to enhance strength, hardness, or wear resistance.

New Metallic Materials: Materials with special physical, chemical, or mechanical properties, such as shape memory alloys, superconducting materials, and nanometallic materials.

Common metallic materials mainly include carbon steel, alloy steel, and cast iron.

Carbon steel is a type of iron–carbon alloy, mainly composed of iron and carbon, with a generally low carbon content not exceeding 2.14%. According to carbon content, carbon steel can be divided into low-carbon steel, medium-carbon steel, and high-carbon steel.

Alloy steel is a type of steel produced by adding one or more alloying elements (such as chromium, nickel, molybdenum, titanium, etc.) to carbon steel. Depending on the types and amounts of alloying elements added, alloy steel can be classified into low-alloy steel, medium-alloy steel, and high-alloy steel.

Cast iron is also an iron–carbon alloy, but with a higher carbon content, generally exceeding 2.14%.

Principles for the Selection of Metallic Materials in Mechanical Design

In the process of mechanical design, the selection and application analysis of metallic materials is critical to ensuring product performance, service life, and cost. The selection of metallic materials should follow three core principles:

Magnitude and Nature of the Load on Metallic Materials.During operation, metallic materials are subjected to loads that include their own weight as well as externally applied forces, which together constitute the total load. Selecting materials with higher load-bearing capacity helps enhance the continuous working ability of mechanical equipment, ensures long-term stable operation, and further improves the overall efficiency of the machine.

Special Operating Environment of Components.Different metals have varying coefficients of thermal expansion, leading to different degrees of volume change with temperature variations. For components operating in highly corrosive or high-humidity environments, the materials must possess good corrosion resistance and rust resistance. Wear resistance is also an important consideration, as physical contact in mechanical transmission causes cumulative wear, which ultimately affects the service life of the equipment.

Complexity of Component Structures and Processability of Materials.Metallic materials often undergo various manufacturing processes such as casting, forging, welding, and machining. Therefore, materials with good castability, forgeability, weldability, and machinability should be selected to ensure manufacturing efficiency and the quality of finished products.

International Gap in Advanced Materials and Our Company’s Advantages

Although China’s materials industry has made remarkable progress, gaps still remain compared with developed countries such as those in Europe, the United States, and Japan, particularly in fields like aerospace and precision instruments. In areas such as high-strength alloys, high-temperature-resistant materials, and semiconductor raw materials, domestic products still require improvement in terms of purity, fatigue life, and corrosion resistance. Certain high-end specialty materials still rely on imports.

This gap is particularly evident when comparing specific materials. Taking cold-work die steel as an example, although China’s Cr12Mo1V1, Japan’s SKD11, the United States’ D2, and Germany’s 1.2379 share the same chemical composition, their performance differs to some extent. Ordinary domestic Cr12Mo1V1 wear-resistant alloys are generally inferior to SKD11 and tend to form carbide clusters, resulting in relatively poor chipping resistance. SKD11 produced by Hitachi Metals and Daido Steel, with its extremely high purity, ultrafine carbide particles, and uniform carbide distribution, achieves more stable heat treatment dimensions, superior polishing performance, higher wear resistance, and better toughness compatibility. Under ASTM standards in the United States, D2 steel, after heat treatment, has a cold white appearance and higher hardness than SKD11, but lower toughness; under high stress it is prone to generating micro-notches. Germany’s 1.2379, by contrast, offers greater compressive strength compared with SKD11.

However, leading domestic special steel enterprises such as Dongbei Special Steel Group and Fushun Special Steel have significantly improved the overall performance of Cr12Mo1V1 by introducing advanced international smelting equipment and production technologies. The Cr12Mo1V1 they produce has reached the level of international counterparts in key indicators such as purity, carbide uniformity, and heat treatment stability, making it a viable substitute for imported materials like SKD11, D2, and 1.2379. In demanding fields such as precision molds, high-load cutting tools, medical components, and automotive parts, domestically produced high-end materials have passed multiple international certifications and end-user validations, demonstrating performance consistency and reliability comparable to international high-end materials.

Against this backdrop, our company continues to deepen cooperation with China’s leading materials enterprises, jointly advancing material performance optimization and application innovation, while upholding an uncompromising commitment to quality in the development and selection of every type of domestic material. We carefully select premium suppliers and ensure stability and reliability in key indicators such as purity and uniformity through rigorous spectrographic analysis, hardness testing, and metallographic inspection, thereby meeting high-standard quality requirements. At the same time, the company has extensive experience in utilizing raw materials provided by overseas clients and can align with international material standards such as JIS and DIN. Leveraging the supply chain advantages of the Dongguan manufacturing base, we are also able to conveniently source materials from globally renowned brands such as Kobe Steel (Japan) and SSAB (Sweden) in the local market, effectively shortening procurement cycles and controlling costs.

At present, our company is capable of processing a wide range of materials, including ferrous metals such as steel, stainless steel, and tungsten steel; non-ferrous metals such as copper, aluminum, and titanium alloys; composite materials such as Hastelloy; and non-metallic materials such as POM and PEEK, thereby meeting the diverse needs of high-end manufacturing.