Made in China and Assembled in Europe and the US

Definition of the Machinery Industry

In the industrial system, the machinery industry is a core sector centered on the design, research and development, manufacturing, processing, assembly, sales, and services of machinery. It is regarded as the “industrial backbone” of the national economy—providing essential equipment such as machine tools, engines, and construction machinery for agriculture, industry, transportation, energy, and national defense. Moreover, through continuous technological innovation, it drives automation and intelligent upgrades across various industries, serving as an important indicator of a nation’s industrial strength. Simply put, the essence of the machinery industry is to transform raw materials into mechanical products with specific functions. Its scope ranges from small items such as precision gears and bearings to large-scale outputs like aerospace engines, ten-thousand-ton machine tools, and offshore wind power equipment.

Strengths and Weaknesses of the Machinery Industry in Europe and the United States

The machinery industry holds an important position in several countries and regions abroad. Overall, the industry in these countries is at a relatively high level, demonstrating outstanding performance in technology, manufacturing, and enterprise development.

Developed countries such as those in Europe, the United States, and Japan are at the forefront of technological innovation in the machinery industry. The U.S. machinery and equipment manufacturing sector benefits from its strong R&D system and substantial investment in research, maintaining leadership in materials science, information technology, and automation. Germany demonstrates world-leading manufacturing capacity and technological expertise in mechanical engineering and machine tools, with its CNC machines renowned for their quality and performance—Siemens’ CNC systems being particularly well known worldwide. Japanese companies, through continuous technological innovation, maintain leadership in fields such as precision machinery, automation equipment, and environmental technologies.

Developed countries in Europe and the United States possess sophisticated manufacturing techniques. Japan’s machinery and equipment manufacturing industry is renowned for its lean manufacturing practices and rigorous quality control systems, resulting in products of high quality and strong durability. Germany’s machinery manufacturing sector covers nearly all types of mechanical equipment, and it stands out for its unique expertise in the production of large-scale, heavy-duty, and precision CNC machine tools. Its capabilities in mechanics, electronics, hydraulics, pneumatics, optics, tooling, and measurement technologies are all among the best in the world.

There are many globally renowned machinery manufacturing enterprises abroad, such as Caterpillar, Komatsu, and Hitachi Construction Machinery. These companies offer a wide range of products and hold a significant market share. By increasing R&D investment, expanding markets, and enhancing product quality and service standards, they maintain their competitive advantage and exert strong influence in the global machinery industry.

With the development of technologies such as artificial intelligence and the Internet of Things, the machinery industry abroad is moving toward greater intelligence. Smart machine tools feature functions such as adaptive machining and intelligent fault diagnosis, which enhance processing accuracy and production efficiency. Collaborative robots can work alongside humans, improving workplace safety. For example, in the United States, the machinery and equipment manufacturing sector has widely applied automation technologies, using intelligent production methods to boost both efficiency and product quality.

Although European and American countries have technological and brand advantages in the development of the machinery industry, they also face some obvious shortcomings.

In Europe and the United States, labor, land, environmental, and energy costs are all much higher than in developing countries. The high cost of labor makes the production of many labor-intensive and mid- to low-end products uneconomical, forcing companies to outsource or relocate this portion of their production capacity to lower-cost regions.

The machinery industry in Europe and the United States faces issues of fragmentation or incompleteness in its industrial chain. Many components and supporting services rely on imports, which increases the complexity, instability, and transportation costs of the supply chain. Once global supply chains encounter disruptions, production is significantly affected.

Due to high costs and global competition, a large portion of mid- and low-end manufacturing in some European and American countries has shifted abroad, leading to an “industrial hollowing-out” phenomenon. Although high-end R&D and design remain domestically based, the loss of large-scale production and manufacturing capacity has made the overall industrial ecosystem more fragile. This not only affects employment but also poses challenges to the industrial application of certain key technologies.

Cooperation of European and American Machinery Industries with China

Since the 20th century, the global economy has entered a stage of high integration. With the establishment of international trade organizations such as GATT and the WTO, along with the development of containerized transportation and information technology, large-scale cross-border production and trade have become more convenient than ever before. Enterprises no longer need to complete all stages of production in a single country; instead, they can decompose and distribute production chains across the globe according to different countries’ cost, technological, and resource advantages.

Against the backdrop of reform and opening-up policies, China leveraged its large population dividend, relatively low labor costs, massive government investment in infrastructure, and highly efficient production organization capabilities to rapidly emerge as the world’s largest manufacturing hub. This gave China unparalleled scale and cost advantages in component production across many industries, attracting countless multinational companies to relocate their parts manufacturing operations to China.

As global trade frictions intensify and protectionism rises, many countries have imposed high tariffs on imported finished products. To circumvent these trade barriers and reduce tariffs—thus enhancing product competitiveness—many companies have adopted a strategy of “Made in China for components, assembled locally.” Meanwhile, the development of modern logistics, communications, and information technologies—such as the internet, Enterprise Resource Planning (ERP) systems, and real-time logistics tracking—has enabled enterprises to efficiently coordinate component production on different continents with final assembly, ensuring the smooth operation of the entire supply chain.

The approach of producing components in China while assembling locally exhibits several distinctive features:

Production is no longer concentrated in a single country; instead, component manufacturing and final assembly are distributed across different nations.

This model places extremely high demands on supply chain management, requiring companies to efficiently coordinate the production, transportation, and assembly of components across different countries.

China possesses a mature manufacturing ecosystem, a large labor force, and a well-established supply chain, enabling it to produce high-quality components in large quantities at lower costs.

Assembling products in the target market can help companies bypass or reduce import tariffs and trade barriers on finished goods, making their products more price-competitive and facilitating easier access to the local market.

Assembling close to the consumer market can significantly shorten delivery times, enabling companies to respond more quickly to market changes, make product adjustments, or offer customized services.

Fenghe Machinery has been specializing in the manufacturing and export of precision components for twenty years.

Fenghe Precision is located in Chang’an Town, Dongguan City, Guangdong Province, a renowned hub for mold manufacturing in China. Chang’an boasts a highly complete mold industry chain. From upstream mold steel, mold components, and heat treatment, to midstream mold design and manufacturing, and downstream injection molding and stamping, almost every stage of the process can be supported by local or nearby enterprises. This highly concentrated industrial cluster greatly improves production efficiency and reduces business costs.

After years of development, Chang’an’s mold companies have accumulated a solid technical foundation. The area attracts a large number of engineers, technical professionals, and skilled workers in the mold industry, who master advanced mold design and manufacturing techniques. They are capable of producing complex molds with high precision and quality, meeting the demands of high-end manufacturing sectors such as mobile phones, automobiles, and electronics.

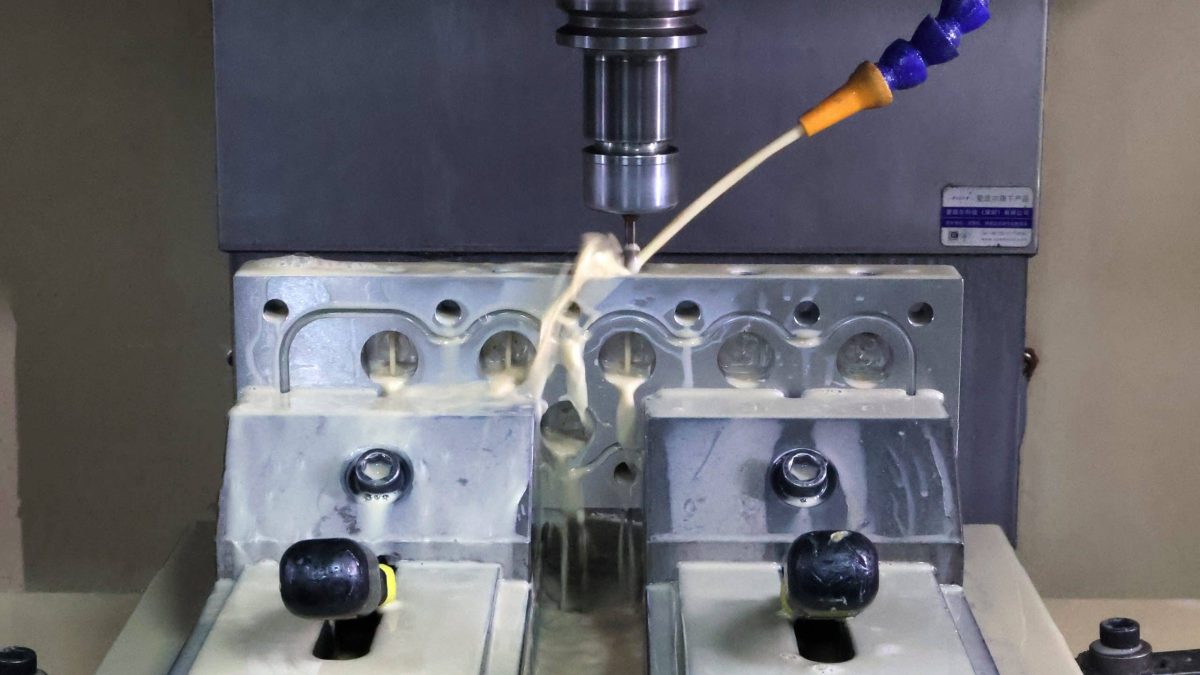

In addition, mold companies in Chang’an are generally willing to invest heavily, equipping themselves with a wide range of advanced domestic and imported machinery, including high-end CNC machines, machining centers, and slow wire EDM machines. This gives them strong competitiveness in both machining precision and efficiency.

Fenghe Precision has accumulated nearly twenty years of manufacturing experience, continually mastering complex component production technologies. Its professional capabilities are far ahead of peers in the industry, consistently providing customers across various sectors with high-quality, reliable products and trustworthy services. The company focuses on delivering highly precise, high-quality, customized solutions for industries such as semiconductor equipment, medical devices, mold components, automotive parts, precision instruments, and automation equipment.

Fenghe Precision boasts an advanced production system and a complete process chain, equipped with high-precision machinery for milling, turning, grinding, cutting, and electrical discharge machining (EDM), ensuring accurate execution of processes and stable, efficient delivery capabilities.

Fenghe Precision is capable of independently designing, manufacturing, and supplying non-standard components such as parts for semiconductor equipment, medical machinery assemblies, core mold components, key automotive parts, precision instruments, precision jigs, and automated equipment. The company can process a wide range of metals, including steel, aluminum, copper, stainless steel, and tungsten, as well as special engineering plastics such as POM and PEEK, and specialty alloys like Hastelloy and titanium alloys.

With extensive experience and comprehensive manufacturing capabilities, Fenghe Precision offers services including heat treatment, milling, turning, grinding, cutting, and electrical discharge machining (EDM). It also provides surface treatments such as TiAlN, TiAlCN, AlCrN, TiN, CrN, TiCN, DLC, PVD coatings, as well as nickel plating and oxidation. Materials are carefully selected according to drawings, and advanced heat treatment and surface processing techniques are applied to optimize product performance.

Fenghe is equipped with a wide range of precision machining equipment, including Mazak CNC machines, Oslon CNC machines, Western wire-cut EDM machines, surface grinders, large hydraulic grinders, and Sodick EDM machines. With this advanced array of equipment, the company is fully capable of meeting customers’ demands for continuous production capacity.

To ensure manufacturing precision, the company has introduced a range of inspection instruments, including internal micrometers, an optical measuring system (2.5D CAD/CAM), a magnetic measuring device, Nikon profile projectors, height gauges, and TESA 400/700 series precision measurement equipment. These instruments are suitable for inspecting various precision components and molds, effectively ensuring workpiece quality and enhancing customer satisfaction.

Fenghe always places customer satisfaction as its top priority, leveraging extensive machining experience, advanced equipment, and precise manufacturing capabilities to ensure the successful fulfillment of clients’ export orders.