Mechanical components:from mass production to customized production

Can mechanical components be produced through customization? This has become one of the core issues in modern manufacturing. With the rapid changes in market demand, the growing number of small-batch, multi-variety, and personalized orders has created a conflict with the traditional model of large-scale, standardized production. As a result, customized production has gradually emerged as a significant development trend in modern manufacturing. In the machining of mechanical equipment, customized production has proven to be feasible and has become a common practice across various industries.

Technical Support for Mechanical Component Production

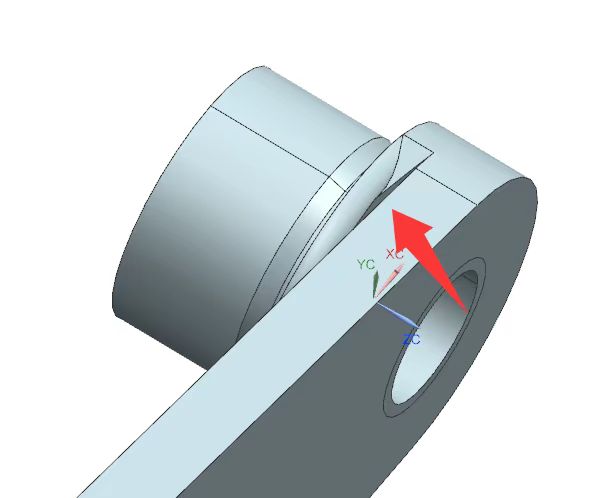

Advances in CNC Machining Technology

As early as the 1980s, Mazak introduced the MAZATROL CNC system, the world’s first CNC system capable of conversational programming in everyday language. MAZATROL CNC machines are characterized by high precision, strong operability, and high efficiency. They can quickly adjust parameters based on customer design drawings to achieve customized production of various components. With functions such as 3D model-based programming, a touchscreen interface, and advanced cycles, these machines are capable of machining complex geometric parts and meeting diverse customer requirements.

Application of 3D Printing Technology

In the MAZATROL CNC system, 3D printing technology is applied to enable customized production of machine components. By building parts through layer-by-layer material deposition, it allows the rapid forming of complex structures and meets customer requirements for small-batch, highly complex customized production.

Development of Digital Technology

AI-powered learning functions can predict the optimal machining process, automatically estimate machining procedures and conditions, and output them as the best program. This ensures high efficiency in design and optimization. By integrating AI technology with CAD, the reliability and effectiveness of component performance verification prior to production can be enhanced, thereby increasing the success rate of customized manufacturing while reducing trial-and-error costs.

High Market Demand for Customized Mechanical Components

Growth in Customized Demand

With the advancement of intelligent manufacturing, the demand for customized mechanical components has been steadily increasing across various industries. For example, in sectors such as semiconductors, healthcare, and automotive, requirements for component performance, precision, materials, and dimensions vary significantly. Standardized industrial products often fail to meet these specialized application needs. Customized production, however, allows solutions to be tailored to specific customer requirements, delivering personalized products and services.

Trend of Small-Batch and Multi-Variety Production

Homogeneous products are becoming increasingly inadequate in meeting customer needs, as demand shifts toward more unique and differentiated solutions. The external market has undergone fundamental changes, and standardized products can no longer satisfy customers’ specific requirements. At present, only customized production can provide delivery solutions featuring multiple items in small batches and diverse varieties, driving a transformation in enterprises’ value creation models.

Further Improvement of the Production Process

Modular Design

Modular design is a major direction in the development of mechanical design. By dividing different production processes of components into multiple standardized modules, various process treatments can be applied according to specific customer requirements. This approach not only improves efficiency and reduces costs but also maximizes the ability to meet diverse market demands.

Flexible Integrated Manufacturing Technology

Flexible integrated manufacturing technology is an advanced approach in modern manufacturing. Relying on automated production systems with minimal human intervention, it enables small-batch and multi-variety production.

Supply Chain Coordination

Supply chain management is the “wisdom baton” of business operations. Guided by customer demands, raw material suppliers, processing departments, and international logistics work in coordination, enabling the smooth flow of information, materials, and capital. This ensures real-time information sharing as well as resource sharing. Throughout business operations, it allows enterprises to deliver products to customers on time, with guaranteed quality, and at a profitable margin.

Challenges and Solutions

Cost Control

It is well known that the costs and time involved in customized production are usually higher than those of standardized production, mainly reflected in procurement, manufacturing, sales, financial, time, and management costs. To control these expenses, enterprises can adopt modular design, flexible integrated technology, and supply chain coordination to improve production efficiency. This not only enables timely delivery of workpieces to customers but also ensures corporate profitability, achieving a win–win outcome.

Long production cycle

The time cost of customized production is relatively high, as processes such as design, procurement, manufacturing, and inspection often result in longer production cycles. Enterprises can optimize the design process and leverage AI technology, flexible integrated manufacturing, and supply chain coordination to enhance production efficiency and shorten delivery lead times.

Quality Control

Customers are placing higher demands on the production quality of customized components. Our clients are mainly from the automotive, medical, semiconductor, and mold industries, requiring machine parts with strict standards for materials, performance, and precision. The old quality management systems can no longer meet current needs. Enterprises must establish more advanced quality management systems and introduce state-of-the-art testing equipment to ensure that every product is delivered to customers with both guaranteed quality and reliability.

Demand for Technical Talent

The mechanical industry has a high demand for skilled technical talent with specialized knowledge and expertise. By attracting highly qualified professionals with extensive experience, enterprises can ensure a strong talent foundation to support customized production.

Future Development Trends

Green and Low-Carbon Production

In mechanical manufacturing, selecting materials with low environmental impact and some recycling value better meets the requirements of green manufacturing. Leveraging advanced technologies can enhance efficiency while reducing energy consumption and emissions.

Intelligent Manufacturing

The manufacturing of non-standard components is gradually entering the “CNC era.” With the MAZATROL CNC system, programming combined with AI algorithms can quickly analyze customer-provided drawings, ensuring the smooth customized production of components and reducing defect rates. Leveraging 5G and Internet technologies, the Blacklake xiaogongdan system allows real-time monitoring of production, enabling timely tracking and feedback on the progress of customer orders.

Product Customization and Strong Customer Loyalty

The engineering machinery sector encompasses a wide variety of categories. Industries such as aerospace, semiconductors, healthcare, automotive, and molds each require different mechanical components, leading to diverse customer demands. Suppliers adopt a specialized customization business model, leveraging professional expertise, flexible production systems, and advanced manufacturing equipment to provide cross-industry, multi-variety, small-batch component customization services according to customer requirements. From workpiece design and process machining to quality inspection, the entire process is fully traceable, ensuring reliable delivery of high-quality products to customers.

Conclusion

In summary, customized production of equipment components not only meets the diverse needs of customers but also brings significant benefits to enterprises, enabling them to better adapt to market changes and seize new opportunities. By leveraging advanced technologies and a well-established production process management system, companies can ensure high-quality production and delivery. Although customized production faces challenges such as higher costs, longer production cycles, and strict quality control requirements, enterprises can effectively address these issues through optimized production processes, flexible integrated technologies, and the adoption of advanced solutions, preparing themselves well for the future.