Nikon Optical Profile Projector (Japan)

Japanese Nikon V-12B Profile Projector, also known as an optical projection measuring instrument or optical comparator, is a measuring device that utilizes the principle of optical projection to project the contour or surface profile of a workpiece onto a viewing screen for measurement and comparison.It serves as an essential inspection tool for quality control engineers to verify the dimensional accuracy and surface features of components before delivery to customers.This article will introduce the working principle, technical advantages, and performance of the Nikon profile projector.

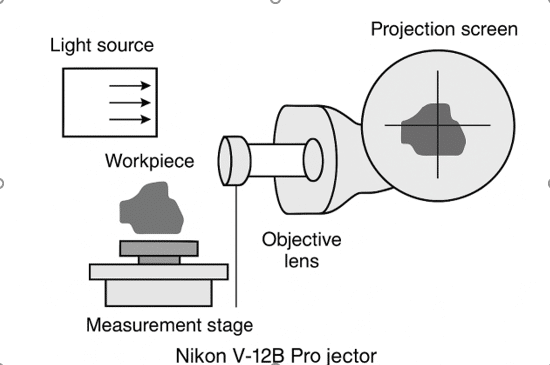

The working principle of the Nikon V-12B is based on optical magnification and image projection measurement. Its core concept is to use transmitted or reflected light to project an enlarged image of the workpiece’s contour onto a screen. Through the optical system and graduated scales, precise dimensional measurements of the component can be achieved.

The optical system uses a halogen lamp or LED light source in combination with a lens system to form parallel light beams, minimizing distortion. Light passes from below through transparent or semi-transparent workpieces, creating a clear contour image and providing uniform, stable illumination. The illuminated workpiece image is optically magnified through the objective lens, with common magnifications of 10X, 20X, 50X, and 100X. The magnified image is then projected onto a frosted screen, forming a high-contrast contour image.The optical lenses are designed in-house by Nikon, ensuring accurate magnification and high image clarity.

Diagram of the working principle of the Nikon V-12B profile projector

During the actual measurement process, light is emitted from the bottom light source and transformed into parallel beams through the lens system before passing through the workpiece. The contour of the workpiece blocks part of the light, creating a clear projected image. This image is magnified by a high-quality objective lens and projected onto the frosted projection screen at the front. The operator can use the crosshair and scale to measure and evaluate the image’s length, angle, and shape.With a high-precision X-Y stage and a built-in linear encoder system, the Nikon V-12B achieves micron-level measurement accuracy. Both transmitted and reflected illumination modes can be flexibly switched to accommodate measurements of outer profiles, hole diameters, groove widths, angles, and complex geometries.The Nikon V-12B profile projector features simple operation, sharp imaging, and stable accuracy, making it an ideal instrument for contour inspection and dimensional control in mold manufacturing, precision machinery, electronic components, and medical device industries.

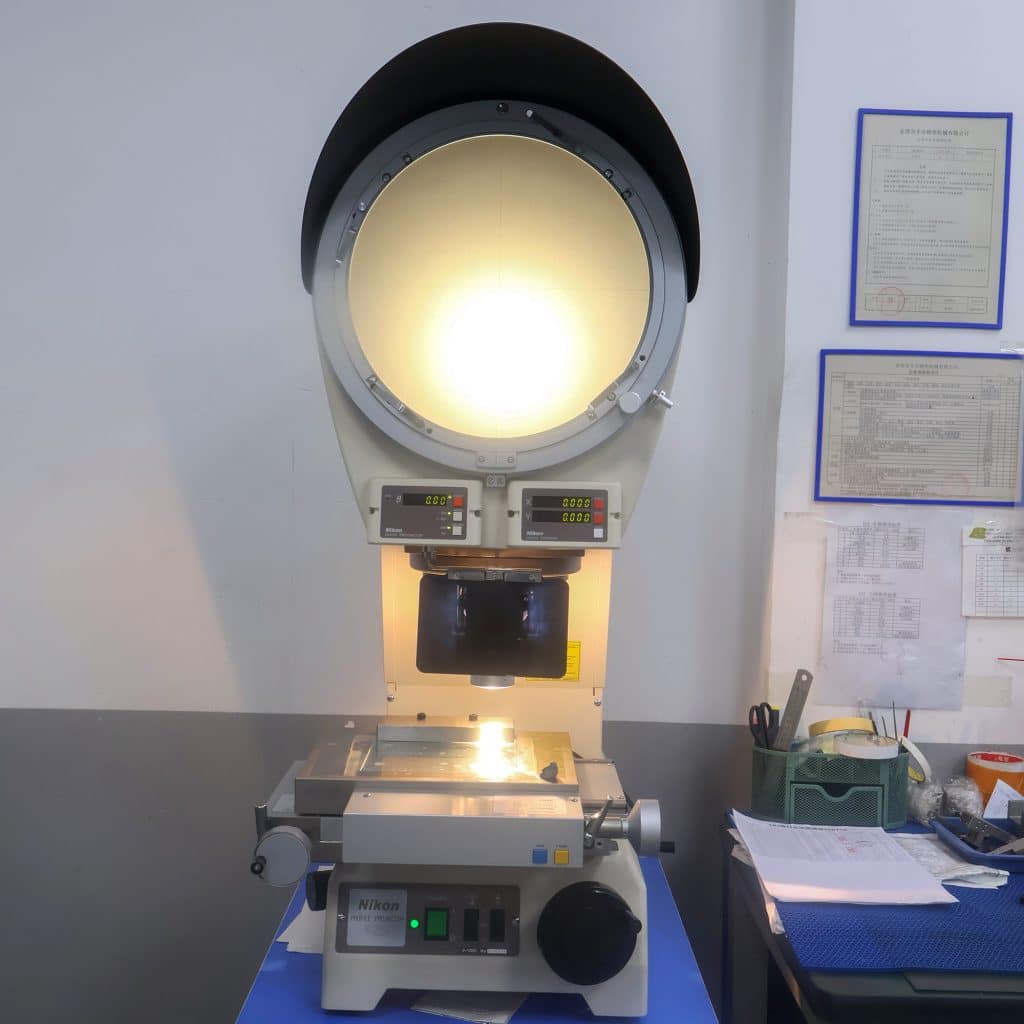

Quality inspector using Nikon V-12B profile projector to inspect workpiece

Our company is equipped with the Japanese Nikon V-12B Profile Projector, which allows us to monitor the precision of workpieces in real time during production, improve workflow efficiency, and achieve digitalized management. This ensures consistently high-quality products and reliable dimensional data, delivering products that meet the highest standards. Our customers are like family, and we always place customer satisfaction as our top priority.