Tungsten alloy designed for extreme conditions

When ordinary materials struggle against wear, deformation, and extreme heat, tungsten steel stands out with its exceptional properties—offering reliable solutions for high-temperature, highly corrosive, and heavy-wear environments. Known as the “teeth of industry,” this ultra-hard material plays a vital role in tackling extreme operating conditions.But what makes it so unique? Let’s start by exploring its foundation—the element tungsten itself.

Our understanding of tungsten often begins with the filament inside everyday light bulbs. However, the true value of tungsten extends far beyond that.

Tungsten steel, also known as cemented carbide, is a type of extremely hard and wear-resistant material produced by powder metallurgy. In Europe, it is commonly referred to as “hard metal.”Its raw materials include tungsten (W), tungsten carbide (WC), cobalt (Co), and mixed compositions from the YG and YT series. Cemented carbide is composed of hard phases and metallic binder phases, perfectly combining the high hardness and wear resistance of the carbide phase with the mechanical strength and thermal shock resistance of the metal binder phase.

The outstanding performance of this material is reflected in multiple aspects. Its Mohs hardness ranges from 8.9 to 9.1, making it 10 times harder than 18K gold and 4 times harder than titanium.

In addition to its high hardness and wear resistance, tungsten steel also exhibits excellent strength and toughness, heat resistance, and corrosion resistance. These properties make it an ideal choice for manufacturing molds, cutting tools, chipless metalworking tools, and wear-resistant structural components, with widespread applications in mechanical engineering, mining and metallurgy, construction, military, and aerospace industries.

To gain an in-depth understanding of the performance characteristics of tungsten steel, we need to focus on several key indicators:

Hardness is the most prominent feature of tungsten steel, commonly measured by HRA and HV. For WC-Co cemented carbides, hardness increases as the cobalt content decreases and the WC grain size is reduced. In terms of strength, cemented carbides are inherently brittle materials, typically evaluated using flexural strength, compressive strength, and fracture toughness. The most common method is the three-point bending test to determine flexural strength, which increases with higher cobalt content but begins to decrease once the cobalt content exceeds 15%.

Density reflects the composition of the grade and is an important indicator for controlling the production process. In cemented carbides, density decreases with increasing cobalt content and is largely independent of WC grain size.

Magnetic properties originate from the ferromagnetism of cobalt, so WC-based cemented carbides are magnetic. By modifying the alloy composition, non-magnetic alloys can be obtained—for example, substituting nickel for cobalt produces alloys with a magnetic permeability close to 1, suitable for magnetic mold cores in forming applications.

Porosity has a significant impact on alloy strength, as pores are the origin of failure. Porosity reflects the presence of microscopic voids in the polished microstructure of cemented carbides. The most effective methods to eliminate or suppress porosity are pressurized sintering or hot isostatic pressing (HIP).

Based on these exceptional properties, tungsten and its alloys have an extremely wide range of applications. High-melting-point alloys of tungsten with refractory metals such as tantalum, niobium, molybdenum, and rhenium can be used as high-temperature structural materials. In aerospace and rocket technology, they are employed to manufacture wear-resistant components, such as valves in aircraft engines, working parts of hot-cutting dies, turbine blades, as well as surface coatings for excavation equipment and plowshares.

In the military field, tungsten steel is commonly used to manufacture shells and gun barrels due to its heat resistance, excellent elasticity, and mechanical strength, as well as its ability to resist corrosion from gunpowder smoke. As early as World War I, German engineers recognized the value of tungsten steel in weapons production—German light machine guns could fire 15,000 rounds, whereas Russian and French light machine guns would fail after only 6,000–8,000 rounds.In addition, tungsten steel components are widely used in cutting tools and knives, such as turning tools, milling cutters, planers, drills, and boring tools, as well as in rock-drilling, excavation, and drilling equipment. From mining, metallurgy, machinery, and construction to transportation, electronics, chemical, light industry, textiles, military, and aerospace, tungsten finds applications across virtually all industrial sectors.

There are various methods for preparing tungsten steel, including traditional powder metallurgy, in-situ reaction, mechanical alloying, liquid-phase sintering, electro-slag remelting, spark plasma sintering, and microwave sintering.

The traditional powder metallurgy method, as the fundamental production process, involves first drying and mixing the powders, followed by pressing to form a green compact, and then sintering and heat treatment to obtain the desired alloy. This method operates at lower temperatures than liquid-phase techniques, with both the matrix and the reinforcing phase in the solid state, avoiding violent interfacial reactions. As a result, the products can be manufactured with minimal or no allowance, reducing the need for machining and improving material utilization.

As the saying goes, “its strength is its weakness”—the extremely high hardness of tungsten steel also brings significant challenges in machining.Tungsten steel’s high hardness and brittleness make it prone to cracking and breaking during processing. In addition, tungsten alloys have poor thermal conductivity, so the heat generated during machining is difficult to dissipate quickly, leading to tool wear and workpiece deformation. Furthermore, controlling the surface roughness of tungsten steel is challenging, requiring specialized machining methods and process parameters to achieve the desired surface quality.

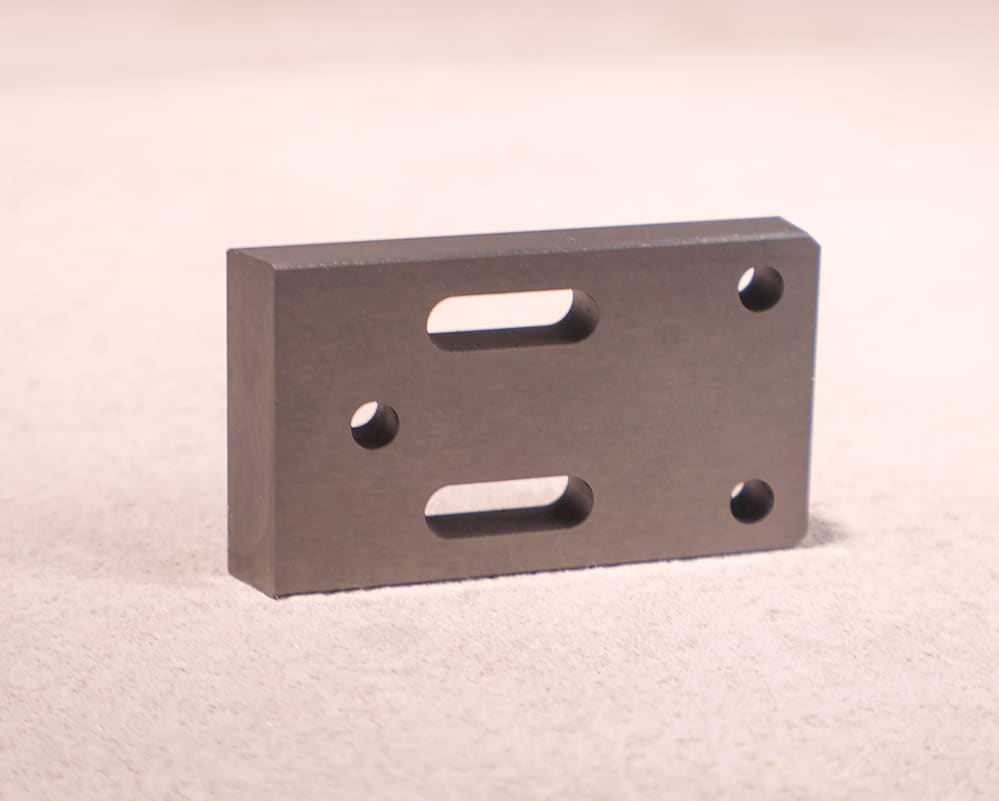

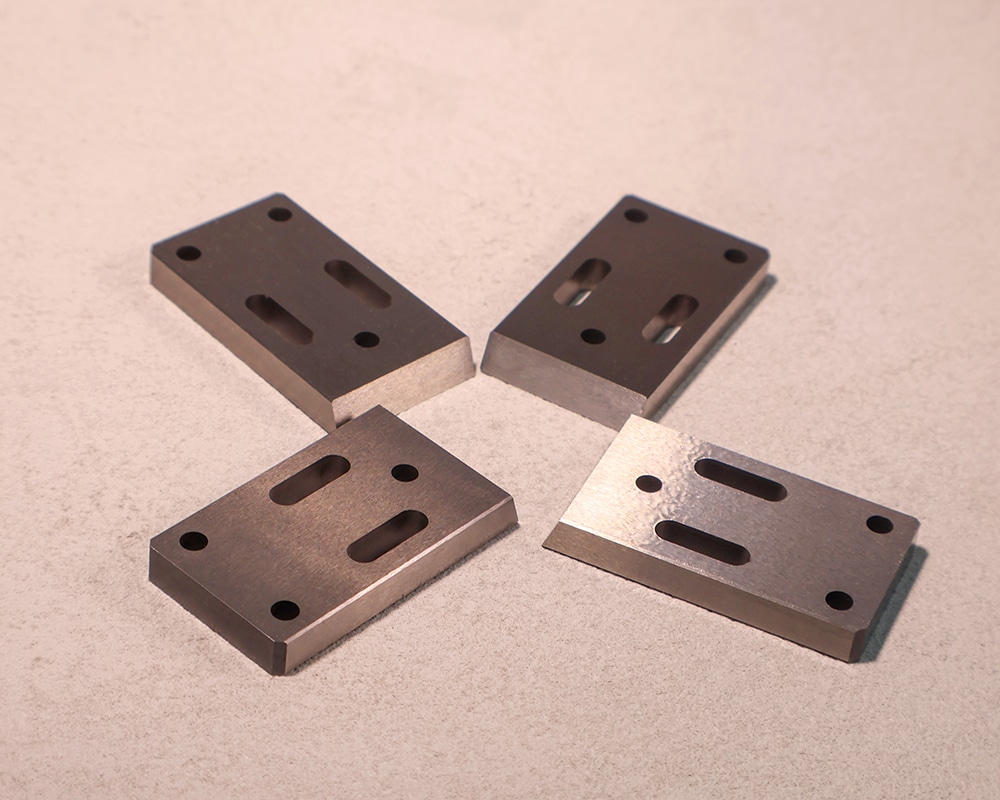

To address these challenges, our company integrates advanced machining technologies such as slow wire EDM, wire cutting, CNC milling, precision grinding, electrical discharge machining (EDM), mirror-finish EDM, laser engraving, and polishing. We possess deep technical expertise and extensive practical experience in tungsten steel machining, successfully overcoming the bottlenecks associated with high-hardness materials and providing clients with high-precision, low-damage, and reliable machining solutions.Processing tungsten steel not only relies on advanced equipment and cutting-edge techniques but also requires rich experience and strict process standards. Our company has a professional tungsten steel machining team, with a rigorous quality control system established from process evaluation, program preparation, machining execution, to inspection and delivery, ensuring that every step meets the highest machining standards and consistently delivers precision components of uncompromised quality to our clients.