01.

Order Management

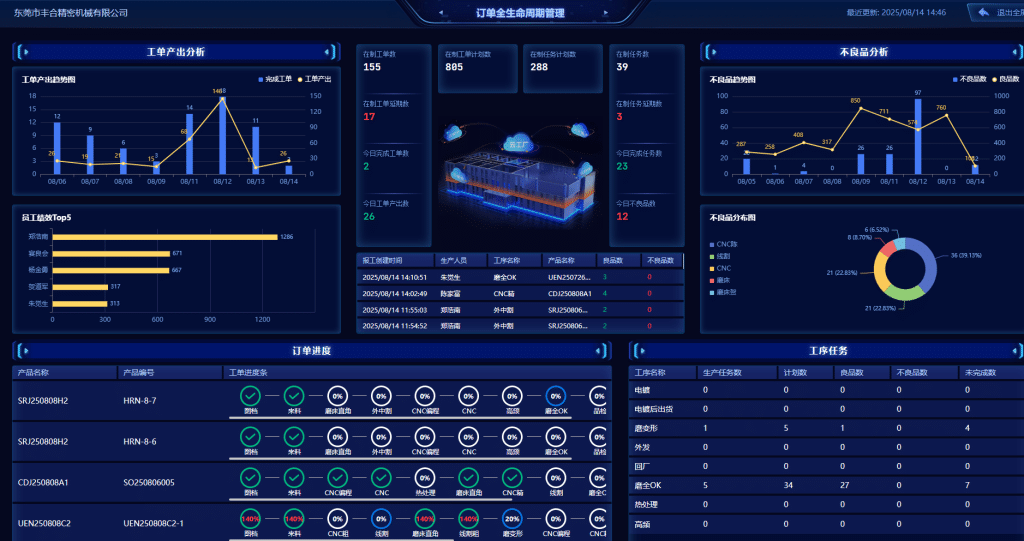

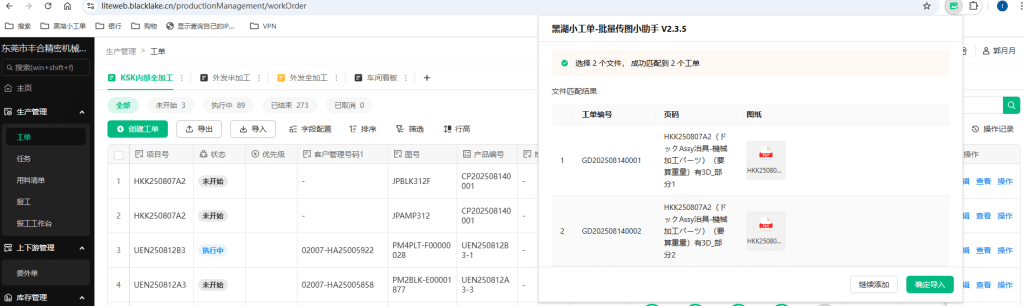

Black lake xiao gong dan is our company’s order management tool. By leveraging cloud computing, internet, blockchain, and artificial intelligence technologies, it enables real-time monitoring of the entire process, spanning transactions, quotations, production, packaging, shipment, delivery, and cargo tracking. It supports the real-time aggregation, collaboration, analysis, and decision-making of production information, realizes cloud-based online manufacturing, and facilitates interconnection and efficient collaboration across the upstream and downstream of the industrial chain.

This tool significantly enhances factory operational efficiency, product quality, and manufacturing capabilities, enabling factories to meet the ever-changing market demands. The digitalization of the production process is an inevitable trend of the times.

In the process of communication and coordination with clients, I always prioritize their needs and provide professional services. By gaining a clear understanding of the company’s situation, I offer tailored and professional suggestions to support the smooth progress of orders. During production, I am responsible for tracking delivery schedules, coordinating production arrangements, handling customs clearance, and organizing shipment. I also maintain close collaboration with various departments to ensure timely completion and delivery of orders.

02.

Design

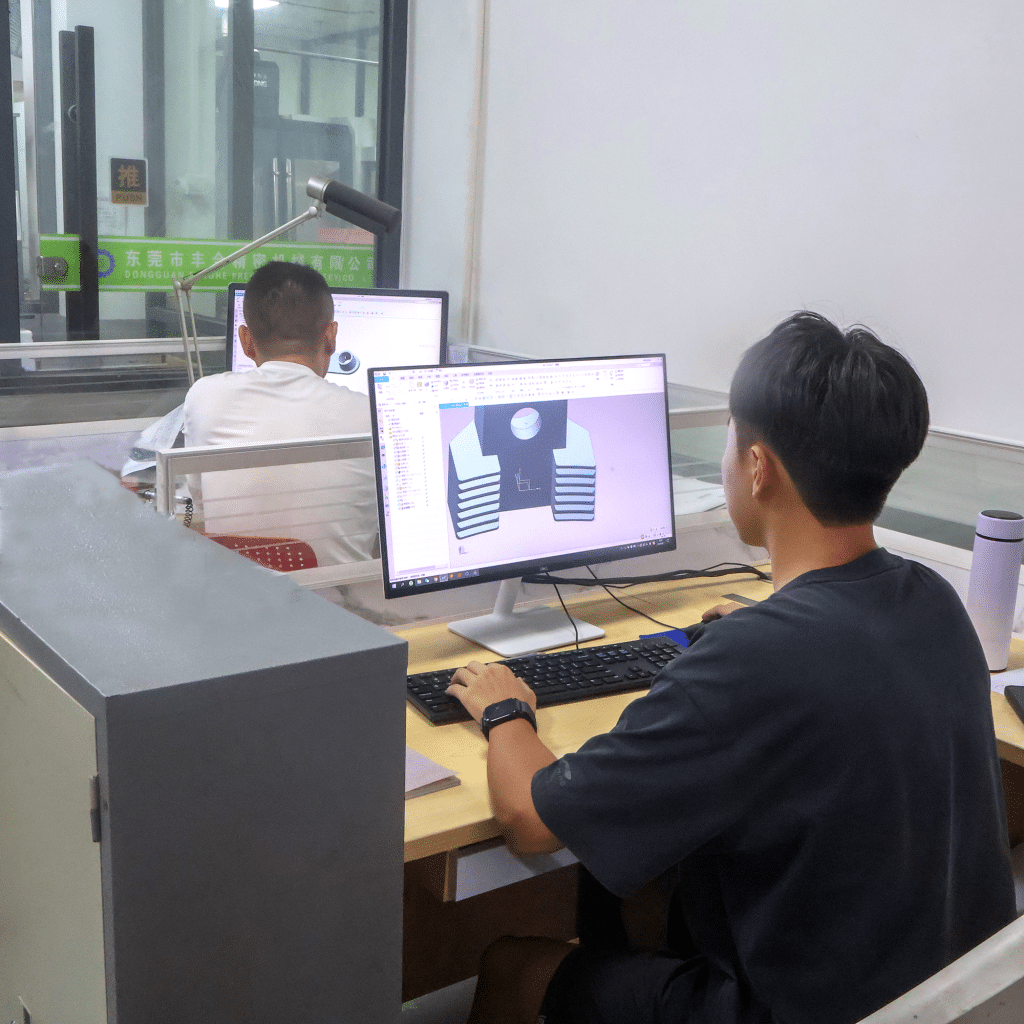

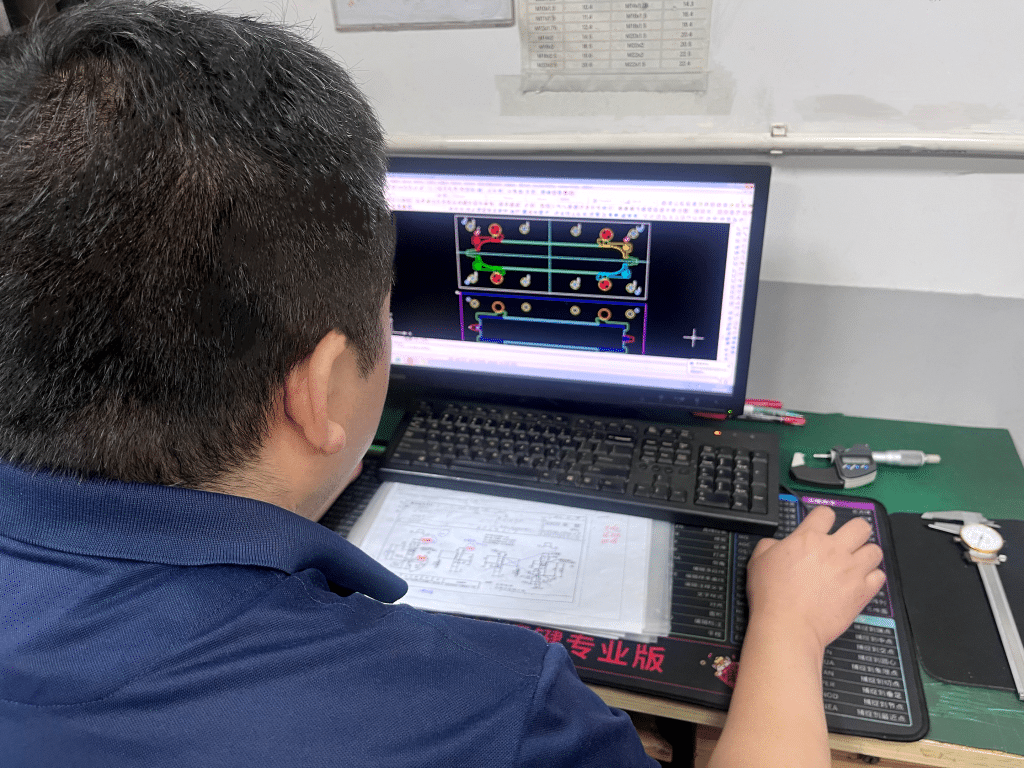

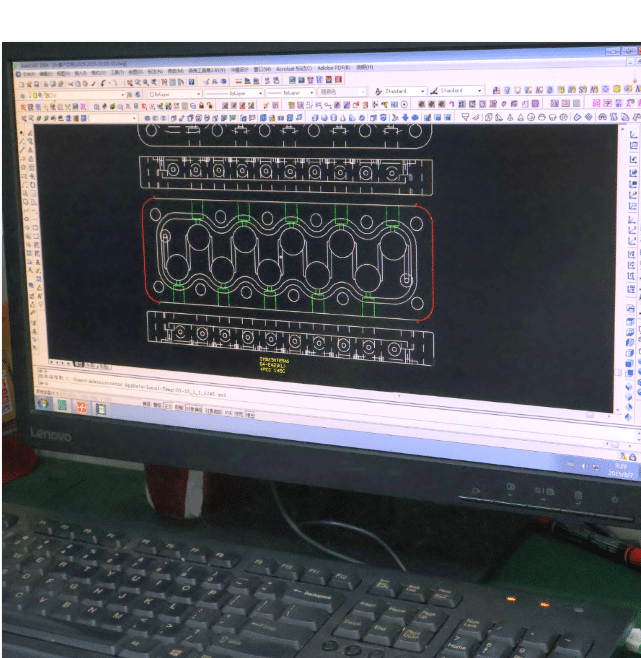

Mold Design:Mold design is a critical aspect of the manufacturing industry, playing an especially vital role in the production of plastic products, metal castings, stamped parts, and die-cast components. It involves designing reasonable mold structures and process solutions based on product shape, material, precision, and production requirements, with the goal of achieving efficient, cost-effective, and high-quality manufacturing.

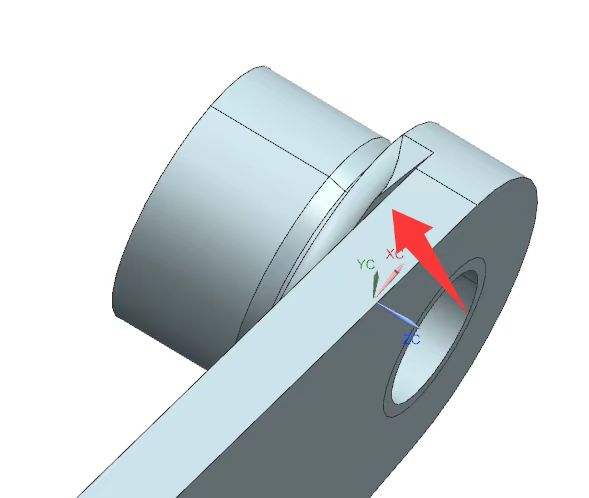

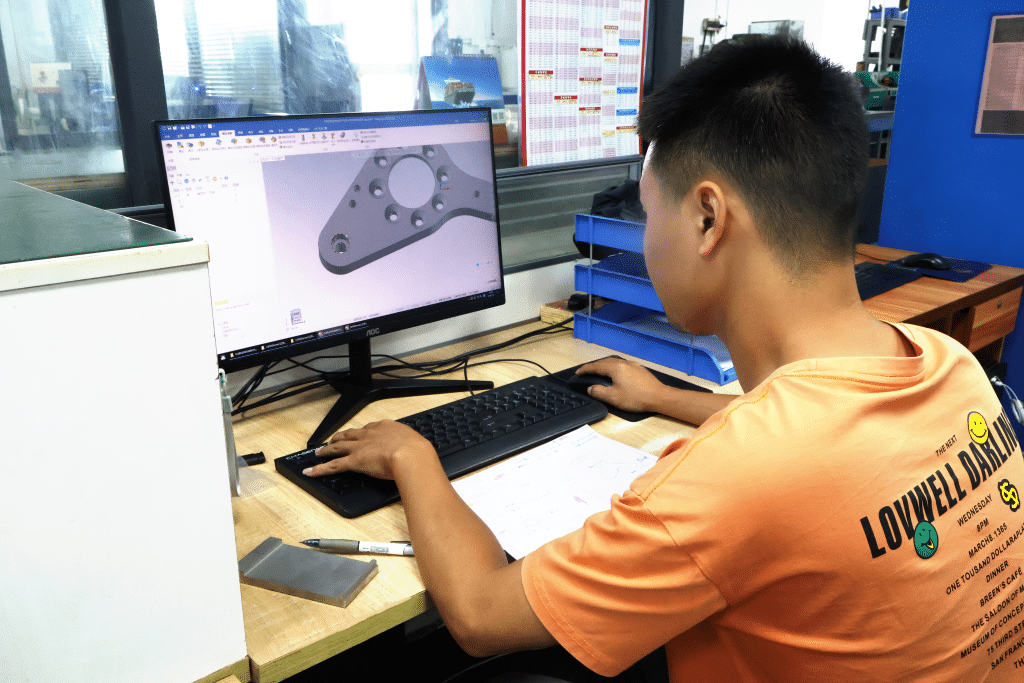

Precision Parts Optimization (3D):We take a comprehensive approach by considering machining processes, part design principles, and assembly applications to provide customers with practical and feasible optimization solutions.

Our company upholds the principle of “Quality First”, delivering proven products to the global manufacturing industry. Over the years, we have remained dedicated to advancing the precision parts manufacturing sector and supporting its sustainable growth.

03.

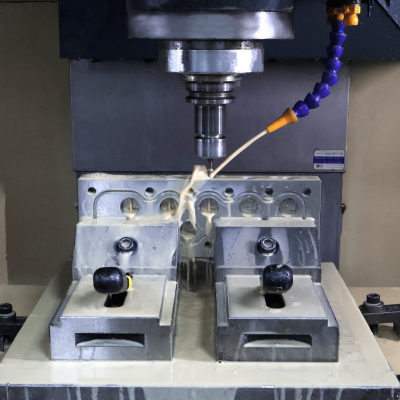

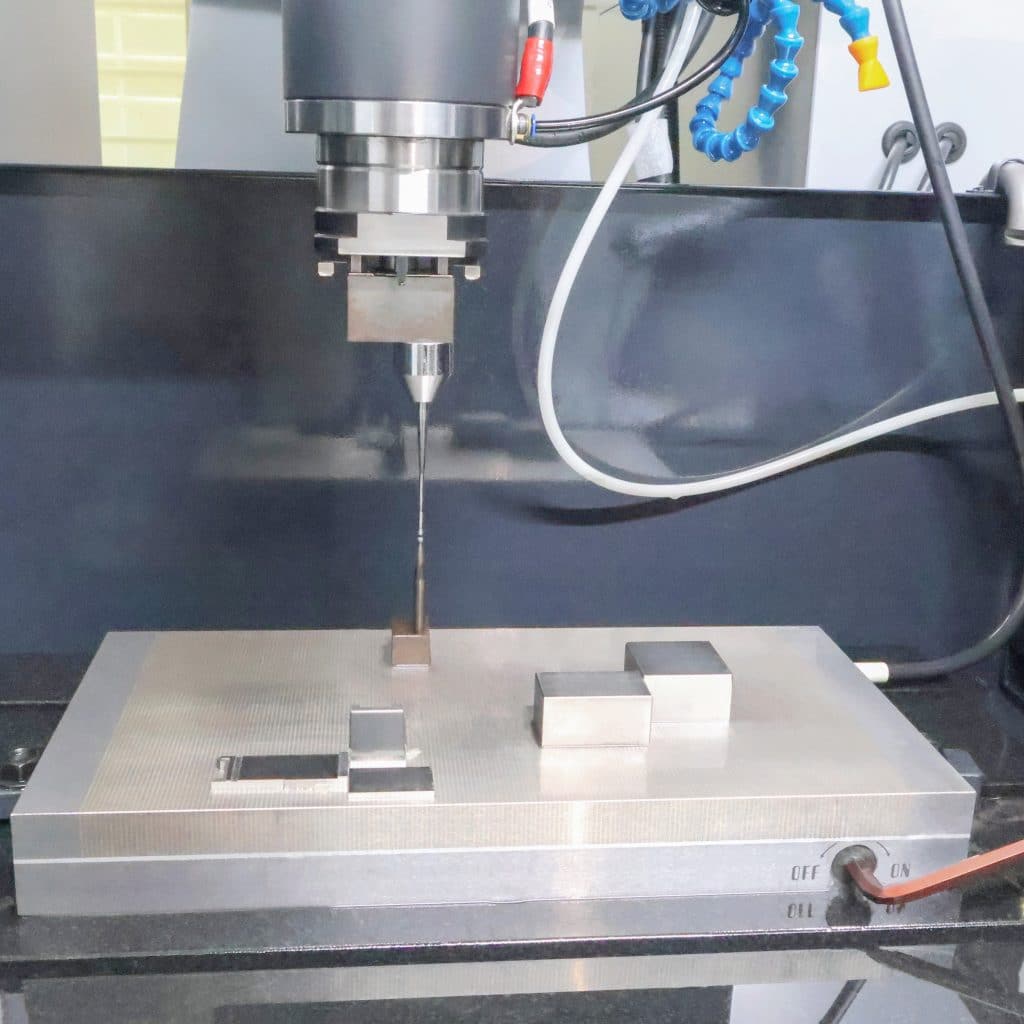

Processing and Production—CNC

Mazak Corporation is a global machine tool manufacturer headquartered in Aichi Prefecture, Japan, specializing in the design, manufacture and sale of CNC machine tools and automation solutions. As one of the world’s largest machine tool manufacturers, Mazak is committed to technological innovation and product development, and constantly launches machine tools that meet market demands. These machine tools boast strong machining capabilities, high production efficiency and more intelligent control systems, providing customers with comprehensive machining solutions.

It uses the FANUC system, developed by FANUC Corporation of Japan, which is a common CNC (Computer Numerical Control) machine tool program in CNC machine shops. With over 60 years of experience in CNC technology development, FANUC is a global leader in factory automation, having accumulated profound technical expertise and extensive practical experience throughout its long-term industry development. This system enables high-speed and high-precision machining, operating extremely stably to achieve excellent surface machining results and accurate positioning. Typically, FANUC independently designs and manufactures its own product components—including servo motors, control devices, software, and sensors—ensuring product reliability from the source.

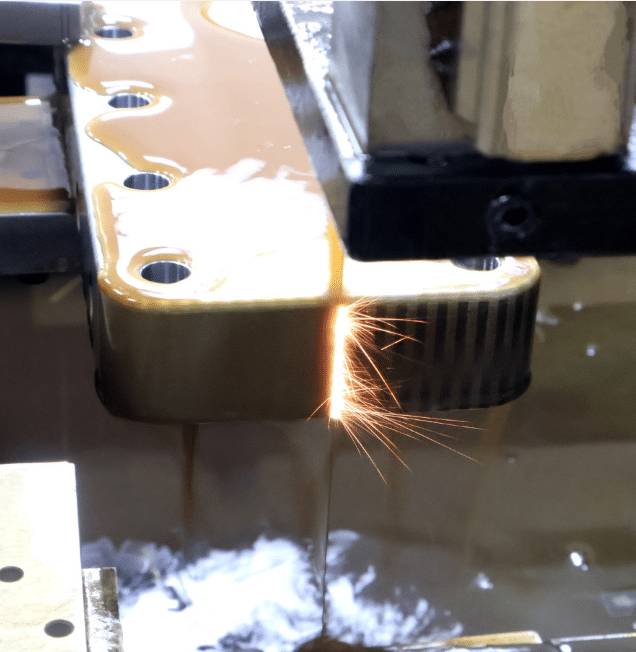

04.Processing and Production-Wire Cutting

The company is equipped with Baqi precision CNC medium-speed wire cutting machines (BQ series from Zhejiang Baqi Intelligent Equipment Co., Ltd.). This equipment adopts advanced pulse power supply and anti-electrolysis power supply technology. For key structures, imported precision linear guides, imported precision ball screws and bearings are selected, which can maintain long-term stable mechanical accuracy and significantly improve the dimensional accuracy and cutting quality of parts. The controller adopts 5-axis digital control (X, Y, U, V, Z), featuring advanced functions such as mirror machining, conventional taper cutting, upper-lower profiled cutting, and 4-axis linkage cutting. It also integrates intelligent operations including lead screw pitch compensation, automatic edge finding, and center finding. It is suitable for processing high-toughness materials such as hardened steel and cemented carbide, as well as complex-structured high-precision parts, with a machining accuracy of up to 0.005mm.

The Seibu Wire EDM (Electrical Discharge Machining) is a high-precision wire-cutting machine tool developed and manufactured by Seibu Denki Co., Ltd. of Japan. Its pitch machining accuracy can reach ±1 micrometer, and it adopts a dual positioning system of guideways and lead screws to ensure machine accuracy, which can meet diverse needs ranging from simple contour machining to precision machining of complex shapes.

Equipped with a reliable automatic wire threading device, it reduces auxiliary machining time and improves production efficiency. As an original imported product from Japan, the machine tool features excellent structural design and sophisticated manufacturing processes, along with stable performance. It has low technical dependence, which can reduce the part scrap rate and ensure consistent accuracy of machined products.

With a wire diameter range of φ0.05-0.3mm and a maximum machining taper of 45°, it can adapt to the machining of parts made of different materials and with complex shapes.

05.

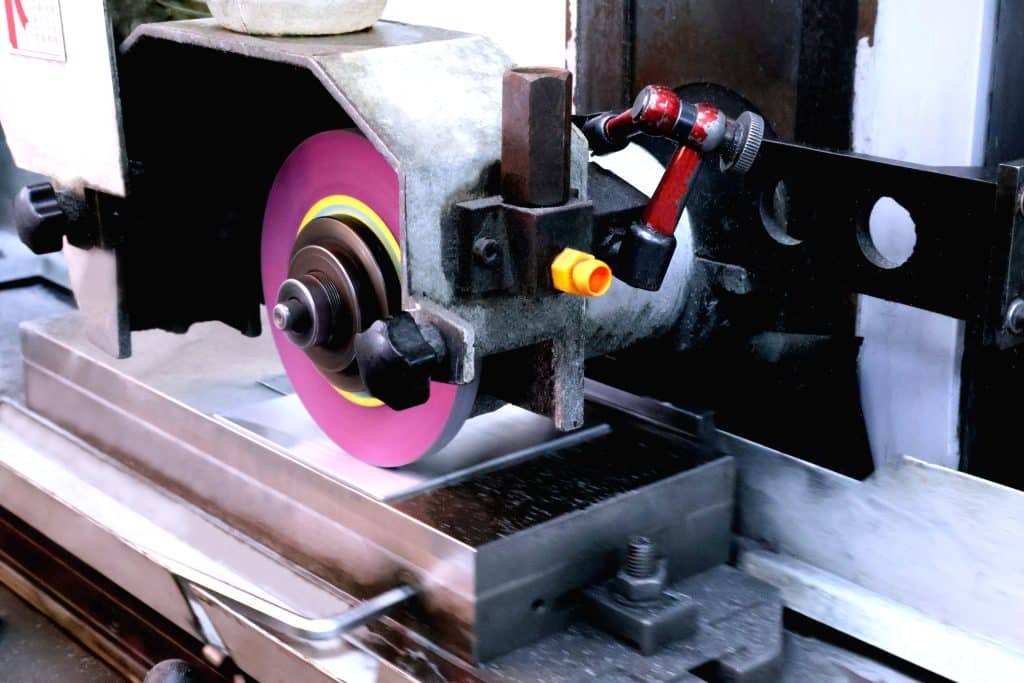

Processing and Production-Grinding

06.

Processing and Production—Discharging

It enables high-grade precision machining, delivering a uniform discharge pattern and a consistent surface finish. Even for fine and intricate geometries, it is capable of performing complex machining without the need for polishing. The machining accuracy can reach ±1 μm, and the surface roughness can be as fine as ±0.25 μm.

07.

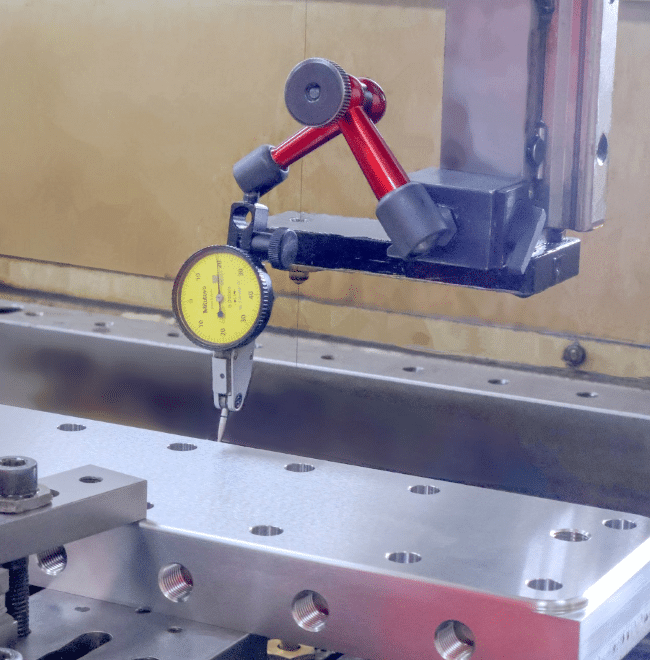

Inspection and Measurement

Nikon Projectors are projection products launched by Nikon Corporation for industrial inspection. The Nikon V-12B is a compact benchtop profile projector introduced by Nikon, mainly used for dimensional inspection and shape observation of industrial workpieces. It can project vertical and upright images, featuring high magnification accuracy, clear image quality, and user-friendly operation. It is suitable for the measurement and inspection of various precision components and molds.

The MFC-101A is a counter device launched by Nikon to be used with its height gauge probes. This device has a minimum reading of 0.1 μm and can switch between 0.5 μm and 1 μm according to measurement requirements. Under standard ambient temperature conditions of 20°C, when the MFC-101A counter is used with the corresponding height gauge probe, its accuracy can reach 1 μm. It is compatible with height gauges of different measurement ranges: when paired with the MF-501, the measurement length is 0–50 mm; when used with the MF-1001, the measurement range is 0–100 mm.

08.

Packing

09.

Shipment

List of Equipment

| Category | Model Number | Manufacturer | Machining stroke(mm) | Accuracy(mm) | Number |

|---|---|---|---|---|---|

| CNC Milling | Mazak VCE570-BL | Yamazaki Mazak | 500*570*780 | 0.003 | 1 |

| CNC Milling | AOSILONG V-850 | Aosilong | 510*510*820 | 0.005 | 3 |

| Milling | Acman FTM-E4 | Fengbao | 350*350*800 | 0.02 | 2 |

| Cutting | Seibu M50B | Seibu | 310*400*500 | 0.002 | 2 |

| Cutting | BQ400 | Baqi | 310*320*400 | 0.005 | 1 |

| Cutting | BQ630 | Baqi | 310*500*630 | 0.005 | 1 |

| Cutting | S-400A | ShengWei | 320*320*400 | / | 1 |

| Grinding and Polishing | SGM-450 | ShuGuang | 150*270*400 | 0.002 | 3 |

| Grinding and Polishing | PMM 4080AHNC | ShuGuang | 400*490*800 | 0.003 | 1 |

| Discharging | AD32LS | Sodick | 220*250*300 | 0.002 | 2 |

| Laser Making | DPL-30W | DaPeng Laser | 30W | / | 1 |

| Projector | V-12B | Nikon | Projection magnification:50X | 0.002 | 1 |

| Vision measuring machine(CAD/CAM system 2.5D) | VMS-3020F | Wanhao | 150*200*300 | 0.005 | 1 |

| Height Gauge | TESA HITE 700 | TESA | 700 | 0.002 | 1 |

| Height Gauge | TESA HITE 400 | TESA | 400 | 0.002 | 1 |

| Altimeter(DIGIMICRO) | MS-11C | Nikon | 0-100 | 0.001 | 1 |